Aluminum insulation roll

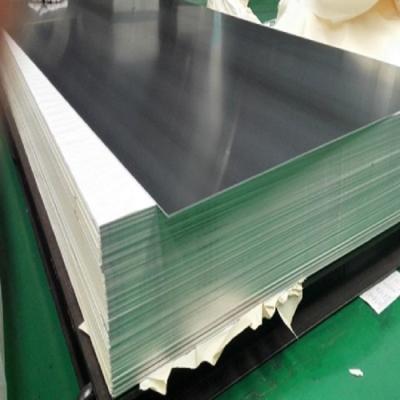

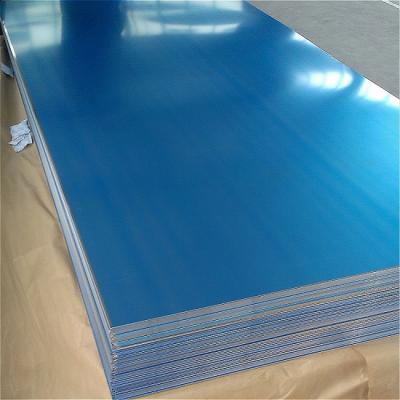

Aluminum coil

Aluminum coil is a kind of metal product for flying shear after calendering and bending.

Silicon has corrosive effect on cemented carbide. Although the aluminum alloy with more than 12% Si is generally called high silicon aluminum alloy, and diamond cutting tools are recommended, this is not absolute. The increasing silicon content gradually increases the destructive power of the cutting tools. Therefore, some manufacturers recommend using diamond tools when the silicon content exceeds 8%.

Aluminum alloy with silicon content between 8% and 12% is a transition zone. Both ordinary cemented carbide and diamond tools can be used. However, when using cemented carbide, tools with PVD (physical coating) method, no aluminum element and small film thickness should be used. Because the PVD method and small film thickness make it possible for the tool to maintain a sharp cutting edge (otherwise, in order to avoid the abnormal growth of the film at the edge, the edge needs to be passivated enough, and the cutting aluminum alloy will not be sharp enough), and the aluminum contained in the film material may cause the blade film to interact with the workpiece material and destroy the combination of the film and the tool matrix. Because the superhard coating is mostly a compound of aluminum, nitrogen and titanium, it may cause edge collapse due to a small amount of peeling off of cemented carbide matrix with the film.

It is recommended to use one of the following three types of tools:

1. Uncoated ultra-fine particle cemented carbide tools

2. Cemented carbide tools with non aluminized coating (PVD) method, such as tin plating, tic plating, etc

3. Use diamond tools

The chip holding space of the tool should be large. Generally, it is recommended to use 2 teeth, and the front angle and rear angle should be large (such as 12 ° -14 °, including the rear angle of the end teeth).

If it is only a general milling surface, you can use an indexable surface milling cutter with a main deflection angle of 45 ° and a blade specially used to process aluminum alloy, which should have a better effect.

Alumina was also made of aluminum by electrolysis in the laboratory in 1808, and was used as a building material on the spire of the Washington Monument in 1884; Aluminum alloy materials synthesized by adding various metal elements have been widely used in all links of the construction industry. Thickness of commonly used aluminum alloy plates: the thickness of advanced metal roof (and curtain wall) system is generally 0.8-1.2mm (while the traditional is generally ≥ 2.5mm)

Shandong Jincheng Aluminum Co., Ltd. produces and processes various aluminum profiles such as aluminum plates, aluminum coils, aluminum strips, aluminum foils, aluminum wires, aluminum beans, aluminum particles, etc. its products cover alloy aluminum coils, alloy aluminum plates, color coated aluminum coils, ultra wide / ultra thick alloy aluminum plates, tensile alloy aluminum plates, anti-corrosion and thermal insulation alloy coils for power plants and chemical plants, alloy aluminum plates for molds, tensile alloy aluminum plates, peritoneum alloy aluminum plates, alloy aluminum plates for electrical radiators Special alloy aluminum plate for curtain wall, antirust alloy aluminum coil, special aluminum coil for spraying / oxidation, antirust alloy aluminum coil, special aluminum plate for signs, color coated aluminum plate, aluminum veneer, patterned aluminum plate, embossed aluminum plate, aluminum strip, aluminum foil, alloy aluminum strip, corrugated pressed aluminum plate, corrugated corrugated alloy aluminum plate, corrugated water corrugated aluminum plate, special aluminum plate for cable tray, and can produce non calibrated aluminum plate according to customer requirements. The products are widely used in heating and power generation, petrochemical corrosion prevention, building decoration, product packaging, solar energy, cosmetics, environmental protection, air conditioning and refrigerator, cold storage refrigeration and other industries. The products are exported to America, Africa and Southeast Asia, and sell well to hundreds of large and medium-sized enterprises in East China, South China, North China and Northeast China.

Our company delivers goods in time, with high quality and low price and considerate service. Common specifications are available in stock; Special size can be customized according to customer requirements, delivery time: about 5 days.

Over the years, national and provincial engineering users have established a stable and long-term business relationship with our company, and the enterprise has always pursued the enterprise spirit of "unity, dedication, pragmatism and truth-seeking", Implement the quality policy of "advanced technology, scientific production, quality first, ensuring that products meet standards and meet user requirements". The leaders of the company welcome customers to negotiate business and exchange technology, and are willing to cooperate widely with people of insight from all walks of life with high-quality products, excellent service, sincere reputation, mutual benefit, win-win and common development.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible