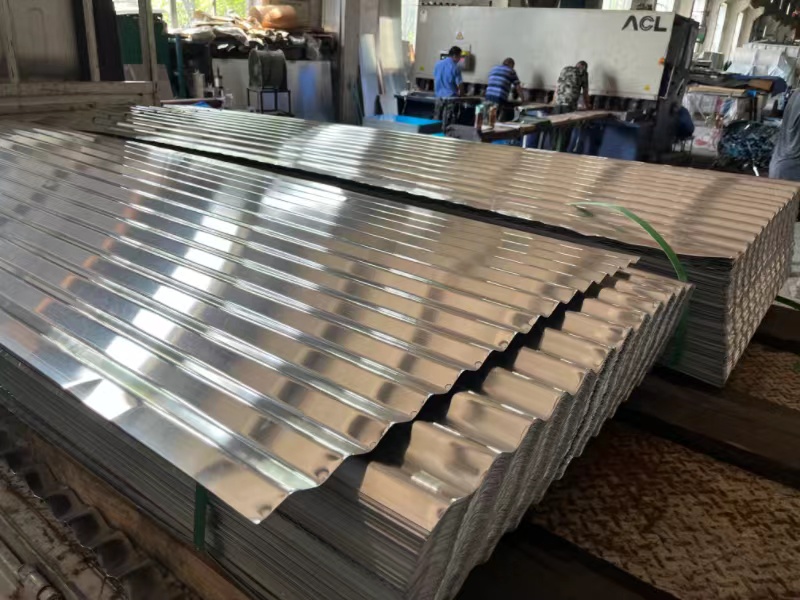

Pressed aluminum plate

What are the advantages of aluminum tiles?

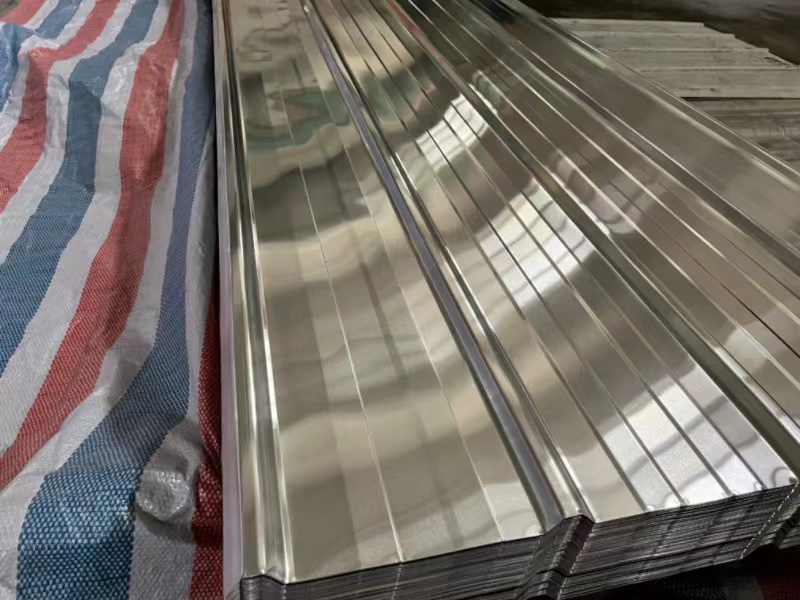

1, light and high strength: aluminum tile (pressed aluminum plate, corrugated aluminum plate, antique aluminum tile) is made of very high quality aluminum coil, the density is only one third of steel, light quality and high strength.

2, good weather resistance: aluminum tile (pressed aluminum plate, corrugated aluminum plate, antique aluminum tile) corrosion resistance is very good, waterproof, moisture-proof and maintenance free, the use of life can be more than ten years.

3, very easy to install: aluminum tile (pressed aluminum plate, corrugated aluminum plate, antique aluminum tile) quality easy processing, construction is very convenient and fast, greatly reduce the intensity of construction.

4, strong decorative performance: aluminum tile (pressed aluminum plate, corrugated aluminum plate, antique aluminum tile) color and modeling types are very many, can meet the needs of different consumers, beautiful appearance and generous, light aluminum color is very bright, color aluminum color is rich anti fading.

5, the value of recovery is high: aluminum tile (pressed aluminum plate, corrugated aluminum plate, antique aluminum tile) because of its corrosion resistance, the value of the furnace will be relatively high after the recovery, the utilization rate of recovery is more than 80%.

Pressed aluminum plate manufacturers,High quality molded aluminum sheet,Global delivery.

Alloy aluminum watts, color aluminum tiles, antique tiles, corrugated aluminum plate, nano tile, commonly used specifications, 840, 750, 850, 900, etc., conventional thickness 0.5 mm0.6 mm0.7 mm0.8 mm0.9 mm1mm1. 2 mm1. 5 mm, supply region: jinan shandong pingyin hole villages and towns in shandong province the jin cheng aluminum industry co., LTD.

5mm aluminum tile is often used for thermal insulation projects in power plants and chemical plants, among which 0.5mm aluminum tile commonly used tile type 750 and 840, 900 type. It is widely used in thermal insulation projects of power plants and chemical plants. In addition, in thermal insulation projects, power plants mostly use 1060 material. Due to its corrosive environment, chemical plants mostly choose rust-proof aluminum alloy, that is, 3003 aluminum manganese alloy material.

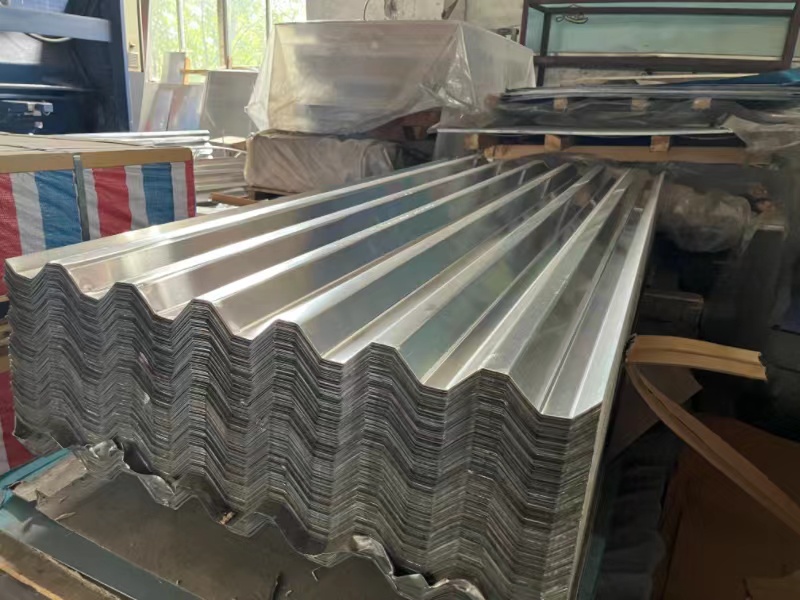

750 type aluminum tile, full name YX35-125-750 type, (V125), or 750 type, the material is made of one meter wide material, the wave height is 35mm, the wave spacing is 125mm, the effective width is 750mm, the overall width is about 800mm. At present, 750 aluminum tile is mainly used in power plant, chemical plant reconstruction project, is a best-selling aluminum tile insulation aluminum tile.

Type 840 aluminum tile, full name YX24-210-840 type, its material is pressed for one meter wide material, wave height is 24mm, wave spacing is 210mm, effective width is 840mm, the overall width is about 900mm. At present, TYPE 840 aluminum tile is mainly used in power plant, chemical plant reconstruction project, and type 750 is especially popular in the market.

836 type aluminum tile, full name YX18-76-836 type wave aluminum tile, its material is pressed for one meter wide material, wave height is 18mm, wave spacing is 76mm, effective width is 836mm, the overall width is about 850mm. This kind of wave tile is a popular wave tile, the early market uses wave tile (there are 14 wave peaks, wave spacing is narrow), and this type 836 wave tile, a total of 12 wave peaks, wave amplitude becomes larger, more conducive to drainage, the effect is better than the old wave tile, 840 aluminum at present.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible