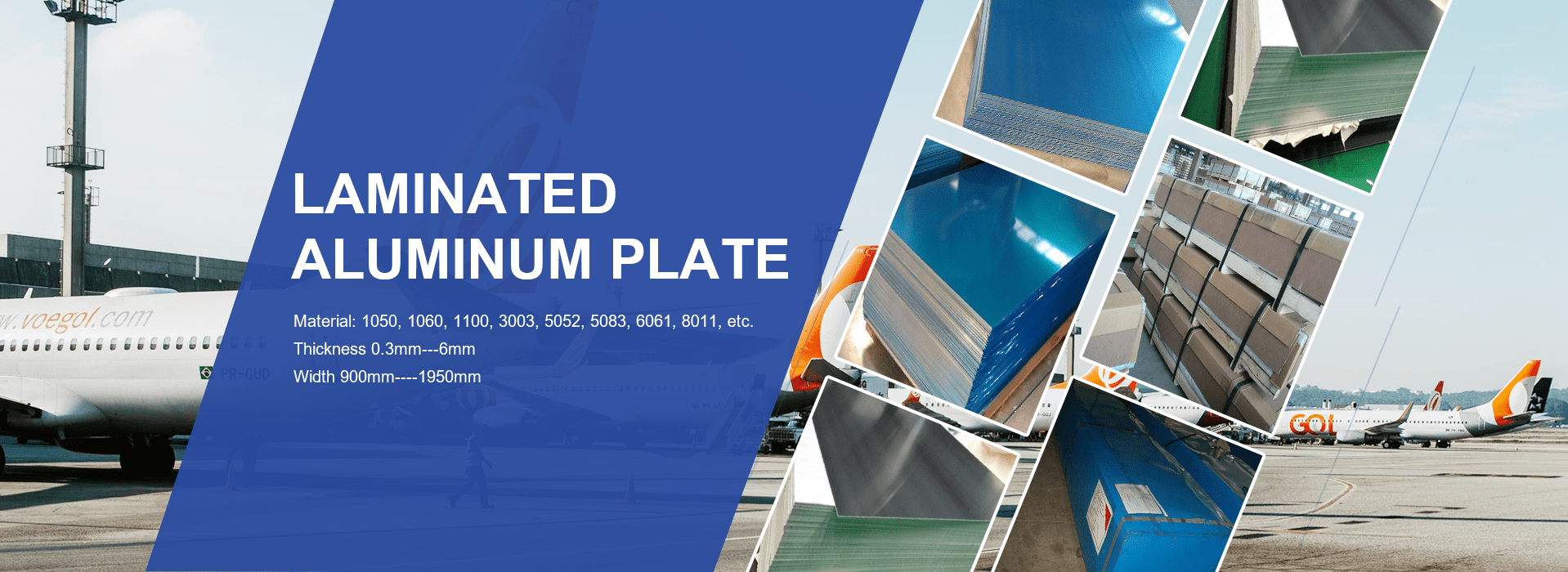

Use of patterned aluminum plate

Classification according to different aluminum sheet alloys

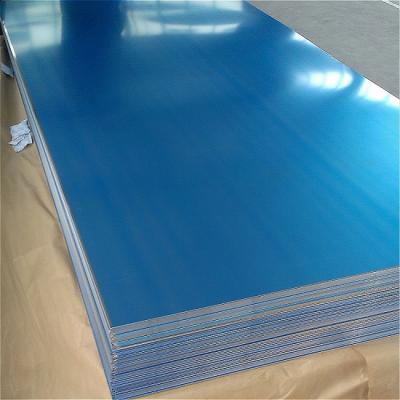

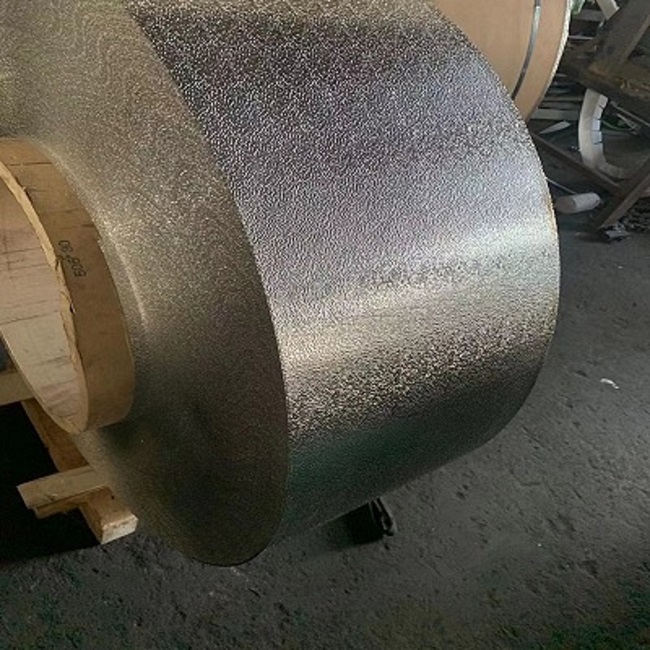

Aluminum plate pattern

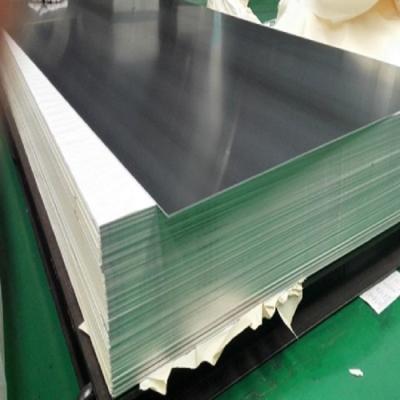

1. Ordinary aluminum alloy pattern plate: the aluminum alloy pattern plate processed with 1060 aluminum plate as the plate base can adapt to the ordinary environment with low price. Usually, this kind of patterned aluminum plate is often used for cold storage, floor and outer packaging.

2. Aluminum alloy pattern plate: It is processed with 3003 as the main raw material. This aluminum plate is also called rust proof aluminum plate, which is slightly stronger than ordinary aluminum alloy pattern plate and has a certain rust resistance. However, the hardness and corrosion resistance of the pattern plate are less than 5000 series. Therefore, this product is used in the rust prevention aspects that are not strictly required, such as truck models and cold storage floors.

3. Aluminum magnesium alloy pattern plate: It is processed from 5000 series aluminum plates, such as 5052 or 5083, with good corrosion resistance, hardness and rust resistance. It is usually used in special places, such as ships, compartment lights, and humid environments. This aluminum plate has high hardness and certain bearing capacity.

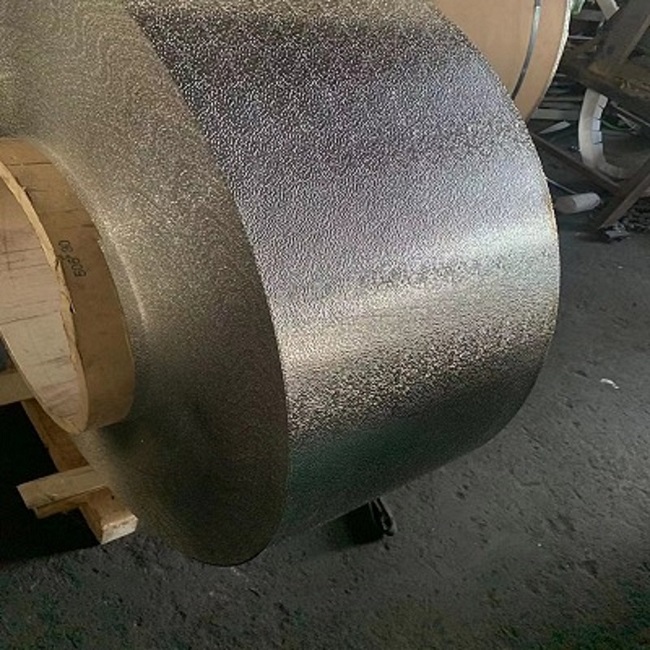

The patterned aluminum plate is a common material at present, which can be used in many places, including home decoration and household appliances. The wide application of aluminum plate is inseparable from its characteristics. There are many kinds of aluminum plates in our daily life. What are the advantages of patterned aluminum plates? The following five points can be summarized.

1. Low density

The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment.

2. Good conductivity

The electrical and thermal conductivity of aluminum is only inferior to silver, copper and gold.

3. Uniform coating and various colors

The advanced electrostatic spraying technology makes the adhesion between the paint and the aluminum plate uniform, with various colors and large selection space.

4. Easy to process

After adding a certain amount of alloy elements, a cast aluminum alloy with good casting performance or a deformed aluminum alloy with good processing plasticity can be obtained. The aluminum plate has light weight, high tensile strength, good elongation and high recovery residual value. Good processability. The aluminum plate can be processed into plane, arc, spherical and other complex geometric shapes by using the process of processing before painting. The aluminum plate is formed in the factory and can be directly processed for the second time without cutting.

5. Good corrosion resistance

The surface of aluminum is easy to produce a dense and firm AL2O3 protective film, which can protect the substrate from corrosion. Through artificial anodizing and coloring, a cast aluminum alloy with good casting properties or a wrought aluminum alloy with good processing plasticity can be obtained. Pvdf fluorocarbon paint with kynar-500 and hylur500 as base materials can not fade for 25 years.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible