Pure Rectangular Aluminum Tube

Material: pure aluminum, specification diameter: 0.4-12mm

Extrusion is the means of profile forming. Firstly, the die is designed and manufactured according to the section of profile products, and the heated round cast rod is extruded from the die by extruder. The commonly used grade 6063 alloy also uses an air-cooled quenching process and subsequent artificial aging process during extrusion to complete heat treatment strengthening. Different grades of heat treatable strengthening alloys have different heat treatment systems.

Features

Thermal conductivity

The thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.

Non ferromagnetism

Aluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.

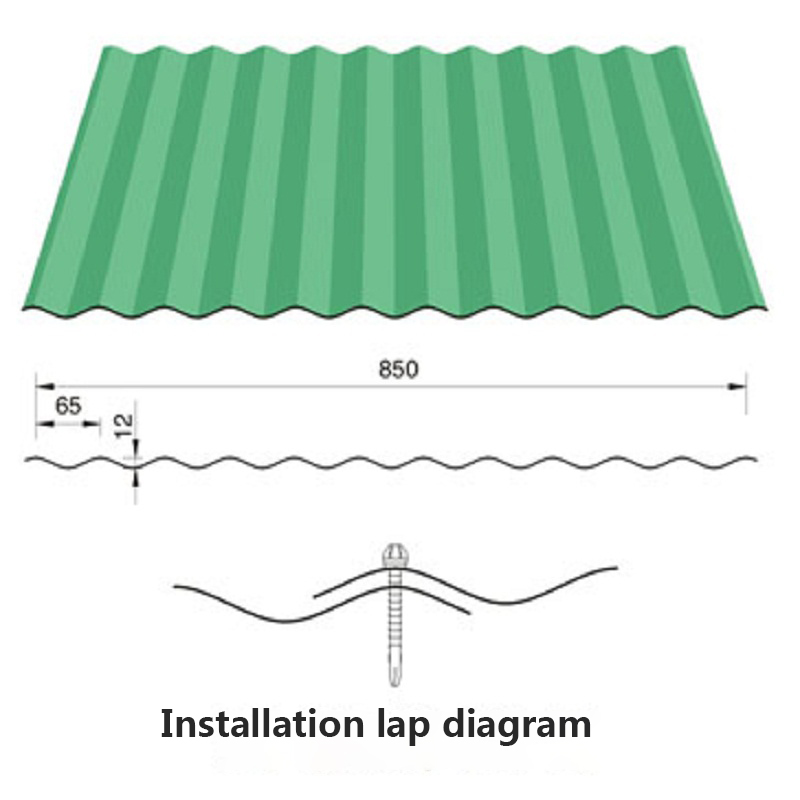

Installation lap diagram

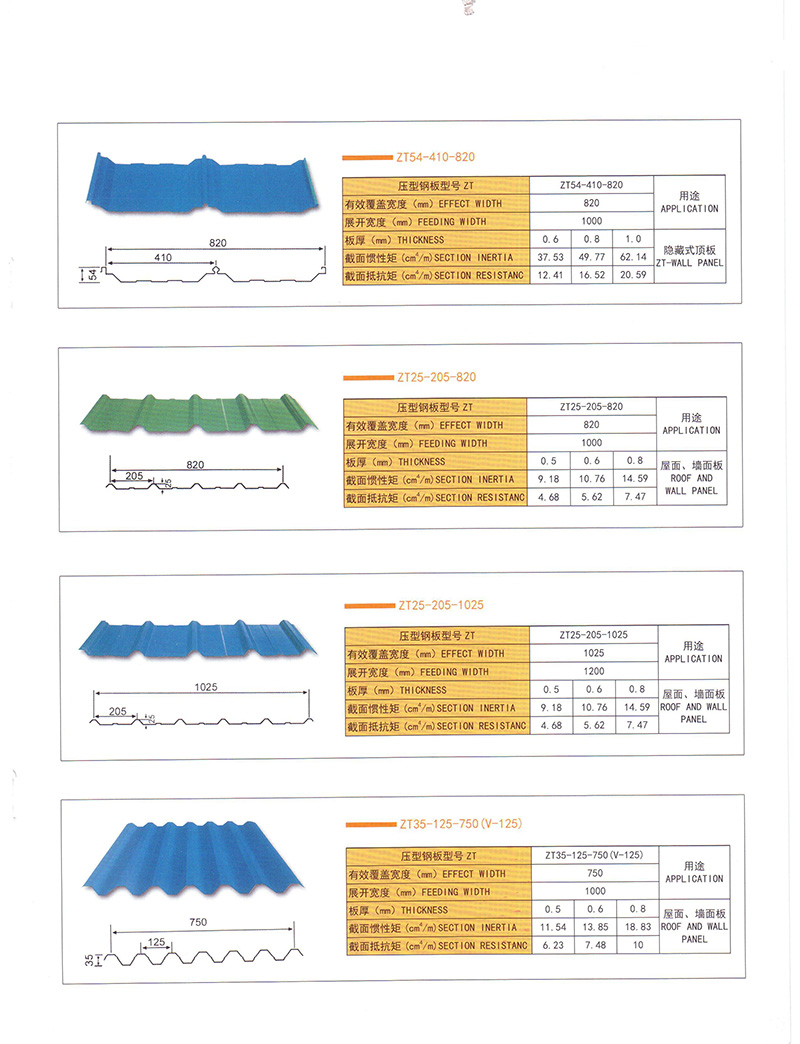

Specification

Related Products

Related News

Submitted successfully

We will contact you as soon as possible