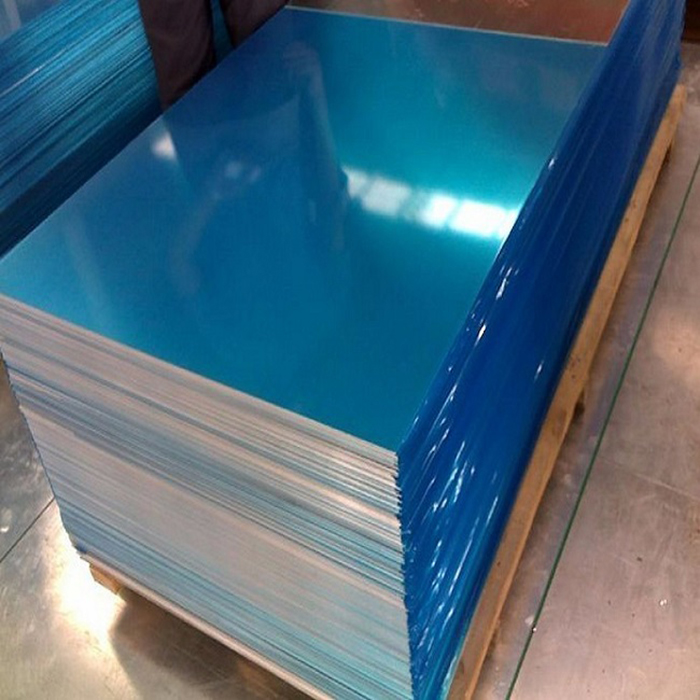

Surface Scratch Treatment Method of Aluminum Plate

Aluminum plate surface scratch is a relatively easy thing to happen in the process of aluminum plate processing. It is often due to improper processing, resulting in surface damage, which seriously affects the beauty of aluminum plate. However, scratches have appeared. The following describes the surface scratch treatment methods of aluminum plate.

The scratch on the surface of aluminum plate can be treated. In brief, there are two physical and chemical methods: physical method is mechanical grinding, including sand blasting, wire drawing, etc. generally, this method is used for deeper scratches. Chemical method generally uses chemical reagent to polish. In brief, it is to use chemical reagent to corrode one layer of aluminum surface. Due to sharp edges at the scratch, the corrosion speed is fast. Lighter scratches can be completely eliminated after chemical polishing. The appearance of chemically polished materials is bright and good-looking. Generally, the combination of the two methods can achieve a good decorative effect on the appearance of aluminum.

Solution to scratch on aluminum plate surface:

1. The working belt on the alloy aluminum plate die needs to be polished smoothly. Whether the empty knife of the extrusion die is enough and whether the surface is smooth.

2. In the process of producing alloy aluminum plate, pay attention to the generation of die lines. Once the line is produced, the mold needs to be removed in time to stop production.

3. In the process of aluminum plate sawing: each sawing requires timely cleaning of the sawdust. Prevent secondary scratch.

4. Similarly, in the process of CNC processing aluminum plate, it is also necessary to prevent the residual aluminum slag scratch on the clamping fixture.

5. There are exposed industrial aluminum profiles or hard inclusions in graphite strips on the discharge track or swing bed, so it is necessary to avoid scratching the surface of aluminum plate when hard sundries contact with aluminum plate.

6. Handle with care in the process of production and handling, and try to avoid dragging or turning the alloy aluminum plate at will.

7. Place aluminum plates reasonably to avoid mutual friction