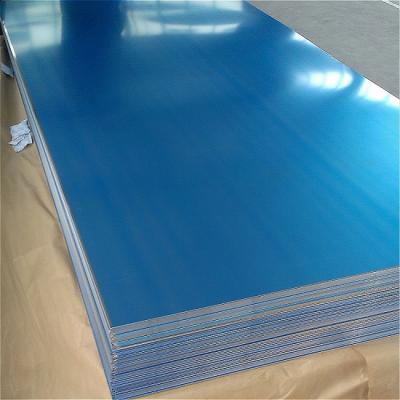

Anode aluminum plate oxidation

The aluminum plate of the anode is oxidized, and a thin layer of aluminum oxide is formed on the surface, with a thickness of 5~20 μ m and a hard anodic oxide film of 60~200 μ m. The anodized aluminum plate has improved its hardness and wear resistance, which can reach 250~500 kg/mm2. It has good heat resistance. The melting point of the hard anodic oxide film is up to 2320K. It has excellent insulation, and the breakdown resistance voltage is up to 2000V. It has enhanced its corrosion resistance ω= 0.03 NaCl salt spray will not be corroded after thousands of hours. There are a lot of micropores in the thin oxide film, which can absorb various lubricants, and is suitable for manufacturing engine cylinders or other wear-resistant parts; The membrane has strong microporous adsorption capacity and can be colored into various beautiful colors. Nonferrous metals or their alloys (such as aluminum, magnesium and their alloys) can be anodized.

anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

advantage

(1) Good processability: the positive aluminum oxide plate has strong decorative property, moderate hardness, can be easily bent and formed, and can be continuously and rapidly punched, which is convenient for direct processing into products without complicated surface treatment, greatly reducing the product production cycle and product production cost.

(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate of the stainless steel has no discoloration, corrosion, oxidation and rust after long-term indoor use. Thickened oxide film (10 μ m) The anodized aluminum plate of can be used outdoors and will not change color when exposed to the sun for a long time.

(3) Strong metal feeling: the anodized aluminum plate has high surface hardness, reaching gem level, good scratch resistance, no paint covering on the surface, retains the metal color of aluminum plate, highlights the modern metal feeling, and improves the product grade and added value.

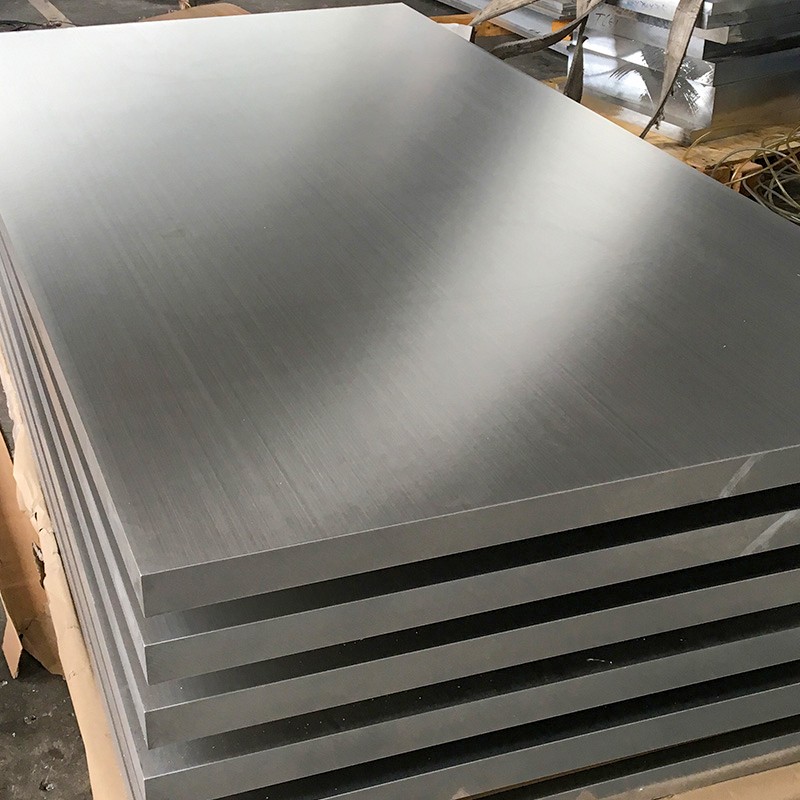

(4) High fire resistance: pure metal products, without paint and any chemical substances on the surface, do not burn at 600 ℃, do not produce toxic gases, and meet the requirements of fire protection and environmental protection.

(5) Strong stain resistance: no fingerprints, no stains, easy to clean, no corrosion spots.

(6) Strong applicability: It is widely used for metal aluminum ceiling, curtain wall panel, aluminum plastic panel, fireproof panel, honeycomb aluminum panel, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible