Aluminum Rod Stock

Material: pure aluminum, specification diameter: 0.4-12mm

Extrusion is the means of profile forming. Firstly, the die is designed and manufactured according to the section of profile products, and the heated round cast rod is extruded from the die by extruder. The commonly used grade 6063 alloy also uses an air-cooled quenching process and subsequent artificial aging process during extrusion to complete heat treatment strengthening. Different grades of heat treatable strengthening alloys have different heat treatment systems.

Basic Instruction

Machinability

The machinability of aluminum profile is excellent. In numerous deformed aluminum alloys and forged aluminum alloys, in addition to in numerous states after the manufacturing of those alloys, the machining traits extrade greatly, which calls for unique system gear or technologies.

Formability

Specific tensile strength, yield strength, ductility and corresponding paintings hardening price dominate the extrade of allowable deformation.

Recyclability

Aluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum.

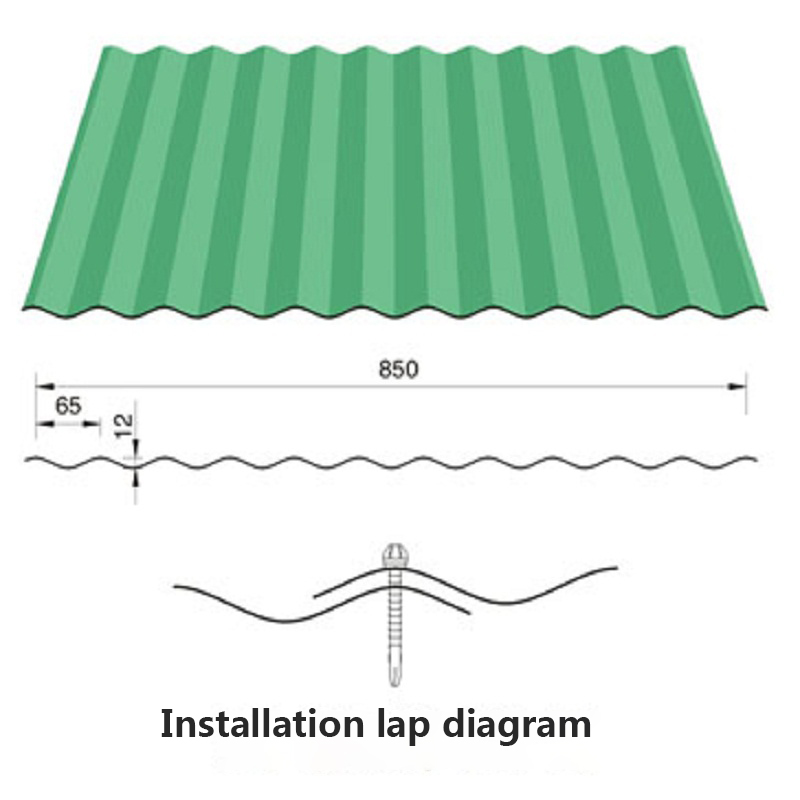

Installation lap diagram

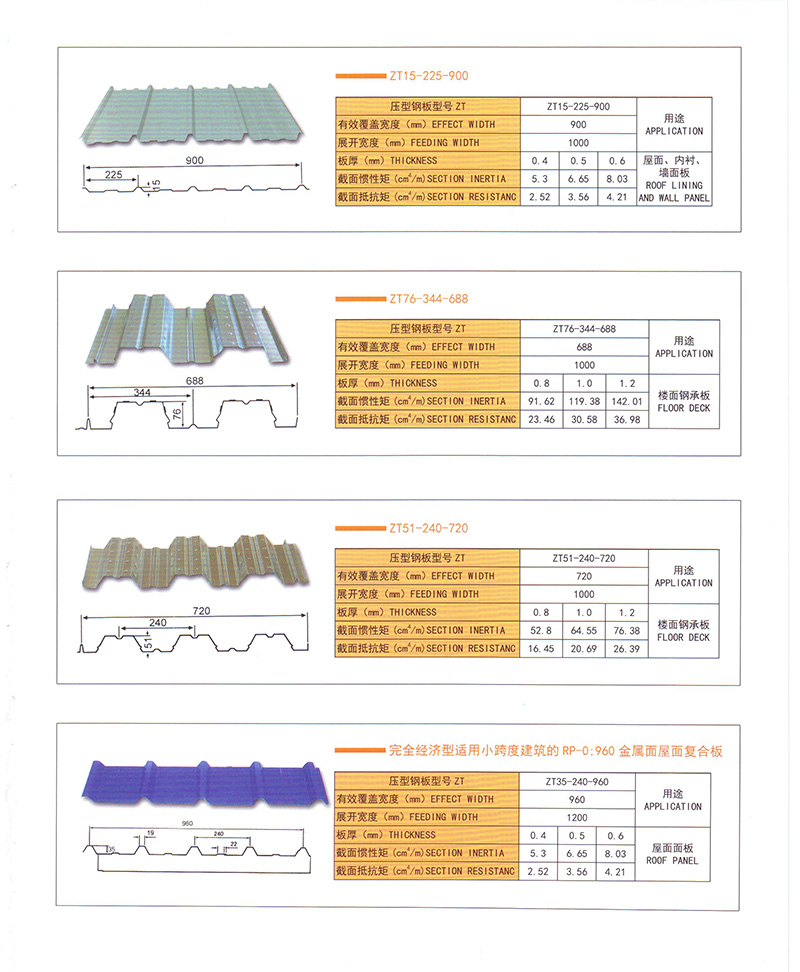

Specification

Titanium plating process

The titanium gold plating process of aluminum profile includes the process steps of material selection, polishing, chemical oil removal, clean water washing, activation and vacuum titanium plating, which is characterized in that it also includes:

a. The pre plating process is to place the activated titanium aluminum profile washed with clean water in the liquid composed of salt, hydrochloric acid and water for chemical treatment. The treatment temperature is normal temperature and the treatment time is until the fierce chemical reaction of the liquid occurs;

b. Electroplating process, in which the bath components include nickel sulfate, nickel chloride, boric acid, sodium dodecyl sulfate, saccharin and brightener. Process conditions: current 3-4A / DM, cathode moving, 5-7a / DM air stirring, bath temperature 50-60 ℃, pH value 3.9-4.2 and electroplating time 15 minutes.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible