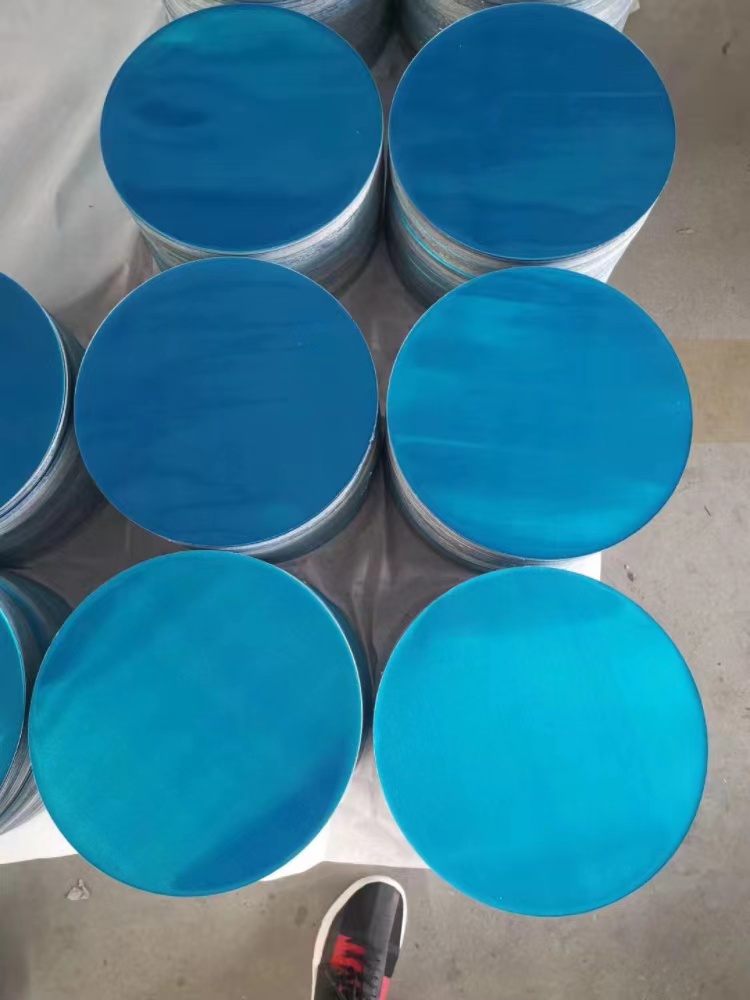

Beautiful and durable aluminum wafer

1. Easy to form: aluminum is light in weight and low in density, which determines that aluminum wafers are easier to form than copper and iron and other metals. When cutting, it often requires only a small amount of power to complete the cutting. It can also be processed in specific applications to better fit the use of the machine. It will not cause uneven fitting and easy falling off, and because it

2. The surface of the aluminum wafer with high reflectivity has high-intensity reflectivity and can reflect radiation and visible light to make the surface smooth and play a good decorative role. Moreover, the aluminum material with good reflectivity has a smooth surface. When used as a cooking utensil, it will have excellent workmanship and strong aesthetic feeling, which can improve the taste of offending, and the high reflectivity reduces the damage to the product

3. Stable performance: the physical and mechanical properties of the aluminum disc are very stable and can be used as a good industrial material. It has strong corrosion resistance and has the characteristics of water and oil resistance, so it can be used in the kitchen and bathroom where oil smoke and stains are easy to occur. Its smooth surface and oil resistance make cleaning more convenient.

Aluminum wafers are mainly used in kitchenware production, sign making and other industries. The commonly used thickness is 1.0mm aluminum wafers and 1.2mm aluminum wafers. Among them, the kitchenware production industry has a large demand for aluminum wafers, especially in foreign countries. Because of its safety, lightness and easy processing, aluminum kitchenware products are more and more favored by customers. The 0.8mm aluminum wafers produced by Chaoyang Aluminum Co., Ltd. are hot rolled and cold rolled, of which 1060 Aluminum wafers and 3003 aluminum wafers are very popular. Customers are welcome to consult and buy.

Aluminum wafer is widely used in electrical appliances, thermal insulation, machinery manufacturing, automobile, aerospace, military industry, mold, construction, printing and other industries, such as kitchen utensils such as non stick pots, pressure pans, and hardware products such as lampshades and water heater shells. It is one of the largest aluminum alloy plate and strip deep processing products.

Our company operates and sells aluminum wafers with a thickness of 0.5-5mm, and can process and customize aluminum wafers with different diameters. The outer diameter can range from 80mm to 900mm. For specific specifications of molds, please consult relevant personnel.

Product features

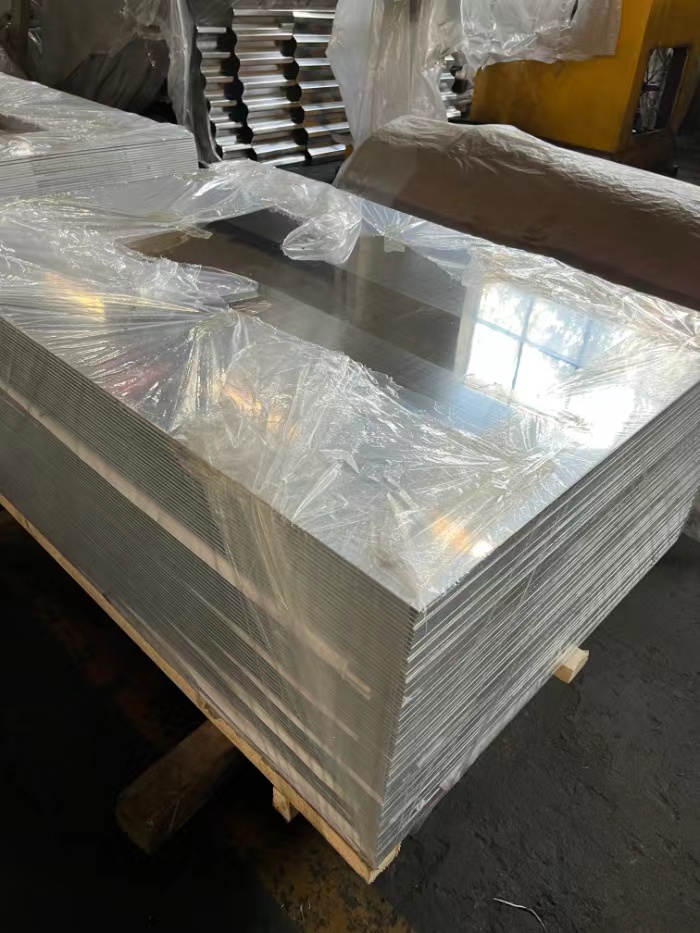

1. The wafer specifications are complete. In addition to the conventional size, the wafer can be provided with the thinnest 0.5mm and the thickest 6.5mm;

2. The surface performance of the wafer is good, ensuring no obvious scratch, oil stain, oxidation, black spot, etc;

3. When the disc thickness is more than 1.0mm, ensure that the edge of the finished product is neat and free of burrs;

4. The good control of the grain size and elongation of the coil in the early stage ensures the excellent deep drawing and spinning performance of the disc, and effectively avoids the possible occurrence of

Bad phenomena such as drawing lines, lotus leaf edges and high ear making rate;

5. Strictly control and test the alloy, state and performance of the coil to ensure the accuracy and diversity of the discs provided;

6. The introduction of advanced and efficient production equipment improves the production efficiency of wafers and the utilization rate of materials, effectively shortens the production cycle, and provides customers with real-time convenience

Services;

7. The wafer classification is detailed, and accurate categories can be selected according to different uses and requirements of customers;

8. Products comply with RoHS and reach environmental protection standards;

9. The product package is firm and meets the domestic sales and international export standards.

As a leading aluminum wafer manufacturer in China, our company (Jinan Chaoyang Aluminum Co., Ltd.) is constantly seeking knowledge and exploring to make the aluminum wafer better and more specialized. We not only strictly control the wafer quality, but also actively introduce advanced production equipment to shorten the supply cycle, constantly optimize and improve the market and customer demand, and provide customized and convenient services for customers.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible