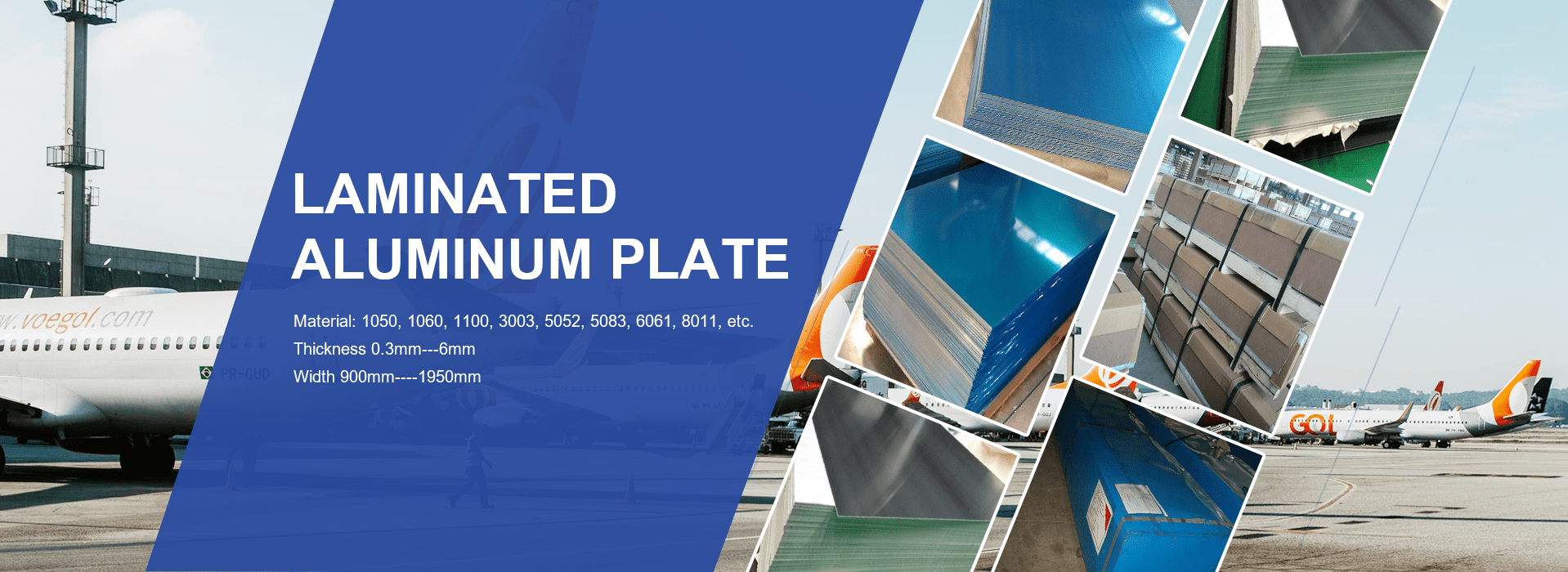

Aluminum disc

1、 Easy to form

The light weight and low density of aluminum determine that the aluminum wafer is easier to be shaped than copper and iron and other metals during processing. It often requires only a small amount of power to cut. It can also be processed in specific applications to facilitate the use of the machine and avoid uneven fitting and easy falling off, And because it is easy to shape, it can also play a protective role as a variety of irregular objects.

2、 High reflectivity

The surface of the aluminum wafer has high-intensity reflectivity, which can reflect radiation, visible light, etc. to make the surface smooth and play a good decorative role. Moreover, the surface of aluminum material with good reflectivity is smooth. When it is used as a cooker, it will have excellent workmanship and strong aesthetic feeling, which can improve the taste of offending, and the high reflectivity reduces the damage to the product, which can well extend the service life of the product.

3、 Stable performance

The physical and mechanical properties of aluminum disc are very stable and can be used as a good industrial material. It has strong corrosion resistance and is waterproof and oil-proof, so it can be used in kitchen and bathroom where oil smoke and stains are easy to occur. Its smooth surface and oil-proof characteristics make it more convenient to clean, reduce the fatigue of cleaning and improve the quality of life for the majority of families, Its strong stability also makes it possible to act as a protective metal.

These advantages of aluminum wafers are the reason why they are popular in the industry and sell so well. The development of aluminum wafers enables them to be applied in different fields such as aircraft manufacturing and electrical equipment manufacturing. The realization of their advantages must first be guaranteed by quality. Therefore, the selection of raw materials and the selection of processing steps and production tools are very important, Only by controlling every detail can we produce high-quality aluminum wafers.

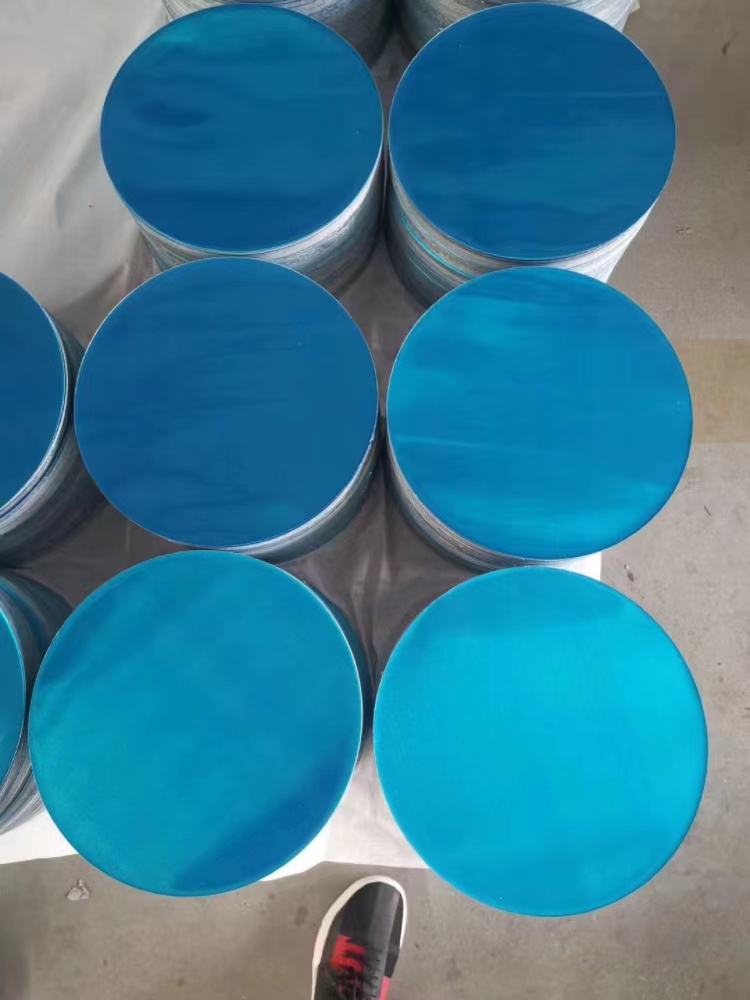

Aluminum wafers are very common in our life. Aluminum wafers can be found in can sealing, non stick pot bottom, traffic signs, lamp covers, and so on. In addition, aluminum wafers are also frequently used in mechanical manufacturing, automobile and other industrial fields. Therefore, when purchasing aluminum wafers, the primary consideration is the use. The use determines whether to purchase hot rolled or cast rolled materials. Cast rolled materials are mainly used for molds, and the elongation of hot rolled materials is higher, Suitable for products to be processed by stamping and stretching. The second is whether the specifications of the products meet their own purchasing standards. Generally, the thickness range of aluminum wafers is 0.3-6.0mm, and the diameter range is 10-3000mm. Due to different equipment and processes, each enterprise can manufacture different specifications. Finally, the delivery date and minimum order quantity of aluminum wafers need to be clear before purchasing.

The use of aluminum wafers has increased in recent years. Aluminum wafers are widely used in electrical appliances, thermal insulation, machinery manufacturing, automobile, aerospace, military industry, mold, construction, printing and other industries, such as kitchen utensils such as non stick pots, pressure pans, and hardware products such as lampshades and water heater shells. It is one of the largest aluminum plate deep processing products. Uses: lamps, lampshades, cooking utensils, aluminum pots, aluminum pots, electric kettle thermal conductive chassis, electric rice cooker liner, smokeless pot, refined iron pot, European pot, non stick pot, aluminum bottles, aluminum barrels, road signs, some aluminum containers, capacitor aluminum shell blanks.

Aluminum wafer is a kind of product obtained by deep processing of aluminum plate. At present, there is a large demand in the foreign market, and most of the aluminum wafers produced in China are exported to all parts of the world. The surface of aluminum wafer is bright and beautiful, which can be shaped and treated.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible