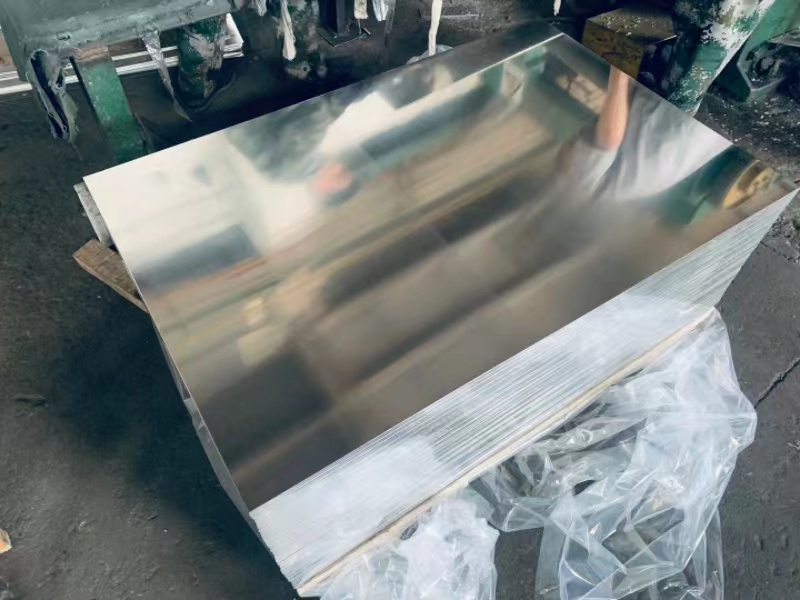

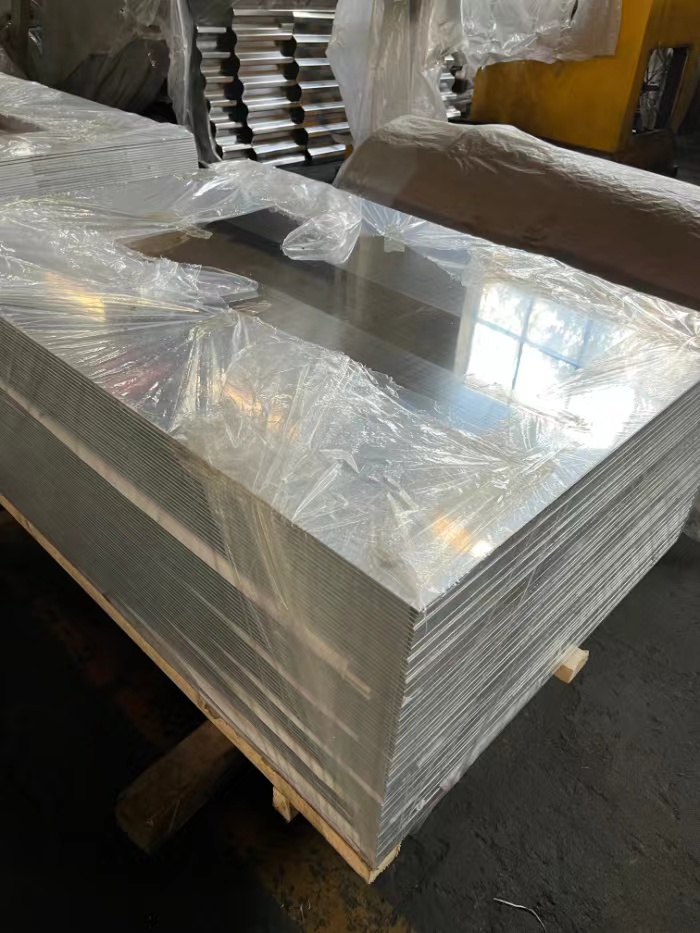

Antirust aluminum plate

Mainly al Mn system and Al Mg system alloys. Because its aging strengthening effect is not obvious, it is not suitable for heat treatment strengthening, but the strength and hardness can be improved by work hardening. The main performance characteristics of this kind of alloy are medium strength, good plasticity and corrosion resistance, so it is called antirust aluminum. It has good weldability and is the most widely used aluminum alloy in welding structure. Aluminum magnesium alloy and aluminum manganese alloy are collectively referred to as antirust aluminum because the alloy components in the middle of the two increase their corrosion resistance. The aluminum manganese alloy is represented by 300330043105. The first type is widely used, the second type is generally used on the cans, and the latter type is used on the wires and other high conductivity requirements, According to the content of magnesium alloy, aluminum magnesium alloy is in the following order: 5005, 525, 5251, 5050, 5052, 5754, 5083, 5056, 5086, etc., which are used in some industries with high corrosion resistance and strength requirements, such as shipbuilding, containers and subway high-speed trains Pressure Machinable aluminum alloy with good corrosion resistance in air, water, oil and other media.

Al Mn series alloy is one of the most widely used antirust aluminum. This alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, and cannot be strengthened by heat treatment. It has good plasticity during semi cold work hardening, low plasticity during cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible