6000 Series Aluminium Plate Sheet

Materials: 1050, 1060, 1100, 3003, 5052, 5083, 6061, 8011, etc

Thickness: 0.3mm-6mm

Width 900mm --- 1950mm

1060 Aluminum plate belongs to industrial pure aluminum, which has high plasticity, corrosion resistance, conductivity and thermal conductivity, but it has low strength, can not be strengthened by heat treatment and poor machinability; It can be gas welding, hydrogen atom welding and contact welding, and is not easy to braze; Easy to bear all kinds of pressure processing, drawing and bending.

Basic Instruction

1060 Aluminum plate is widely used in products with low strength requirements. Products are commonly used in signboards, billboards, building appearance decoration, bus body, wall decoration of high-rise buildings and factories, kitchen sink, lamp holder, fan blade, electronic parts, chemical instruments, sheet metal processing parts, deep drawing or spinning concave utensils, welding parts, heat exchangers, clock surface and disk surface, nameplates, kitchenware, decorations, reflective appliances, etc.

Specification

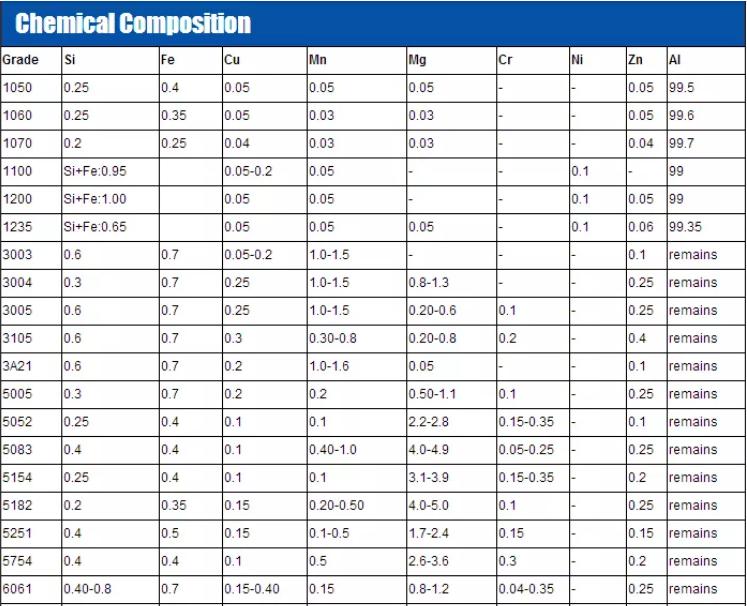

AI(%) | Si(%) | Cu(%) | Mg(%) | Zn(%) | Mn(%) | Ti(%) | V(%) | Fe(%) |

99,60 | 0.25 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.05 | 0.350 |

Component

Folding scope of application

This product is often used in external packaging, mechanical parts, refrigerators, air conditioners, ventilation ducts and other humid environments. This product has good anti rust ability.

3003 aluminum plate is commonly used in ships, ships, vehicle materials, automobile and aircraft plate weldments, pressure vessels requiring strict fire prevention, refrigeration devices, TV towers, drilling equipment, transportation equipment, missile components, armor, etc. 3003 aluminum plate density formula and calculation: length mm * width mm * height mm * 0.00000272

3003 is al Mn alloy, which is the most widely used antirust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum) and cannot be strengthened by heat treatment. Therefore, cold working method is used to improve its mechanical properties: it has high plasticity in annealing state, good plasticity in semi cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability and poor machinability. It is mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other low load parts made by deep drawing: wire rod is used to make rivets.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible