1060 Aluminum plate processing plant

1: Thermal insulation

Aluminum veneer material can be punched, and sound-absorbing mineral wool can be added inside, which has the functions of heat insulation and heat preservation.

2: Sound insulation effect

The sound insulation of aluminum veneer material is as high as 39-32 dB.

3: Fire prevention function

The fire rating of aluminum veneer material is as high as A2, and the melting point is as high as 660 degrees.

4: Moisture proof, rust proof and corrosion proof

Aluminum veneer material has some advantages of wood, but also has the moisture-proof effect and corrosion prevention that wood does not have.

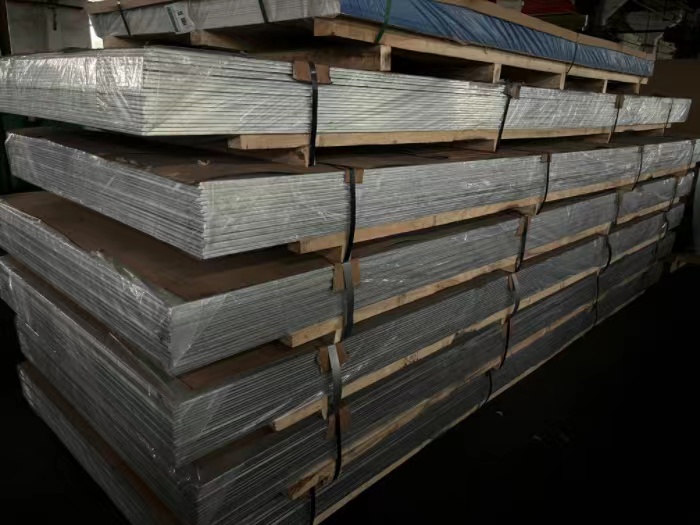

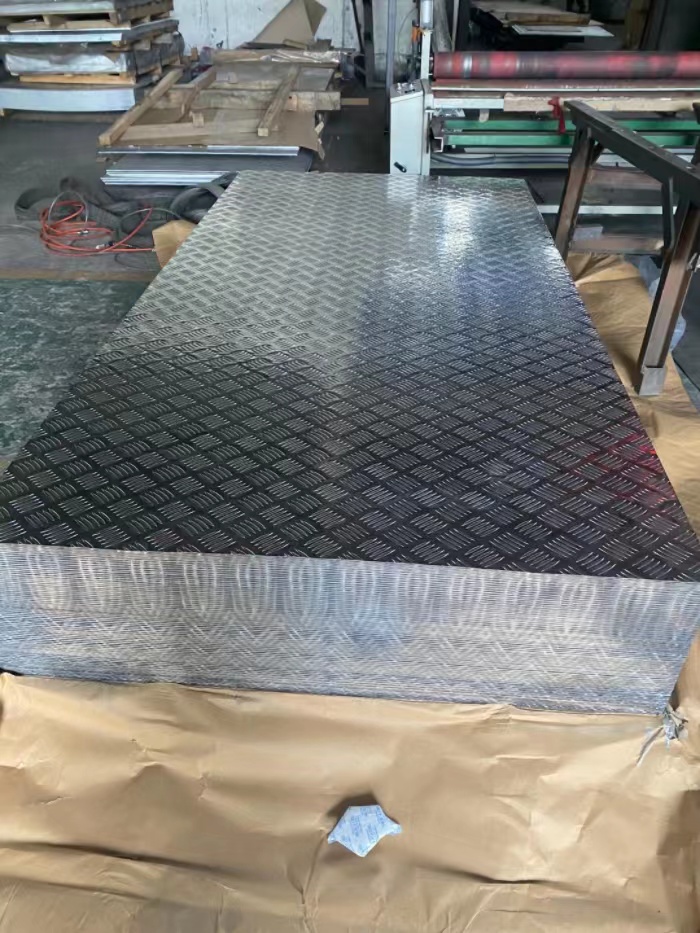

5: The board surface has high strength and is not easy to deform

The high-quality and high-strength antirust alloy aluminum plate is selected as the base material and processed through the processes of cutting, punching, carving, bending and welding. In order to ensure that the plate surface will not deform, stiffeners will be set on the back plate every 500-600mm width. After the sheet metal is formed, the rigidity and hardness will be greatly strengthened through soldering qualitative treatment.

1060-h24 aluminum plate is a kind of 1060 Aluminum plate. In order to reach the state of H24, the metal is strain hardened and then partially annealed, so that its strength is about between annealing (o) and full hardness (h28).

1060-h24 aluminum plate is a kind of 1060 Aluminum plate. In order to reach the h24 state, the metal is strain hardened, and the strength is about between annealing (o) and full hardness (h28).

1060-h22 aluminum plate is a kind of 1060 Aluminum plate. In order to reach the temperature of H12, the metal is strain hardened, and the strength is about one quarter between annealing (o) and full hardening (h28).

The 1060-h26 aluminum plate is a kind of 1060 Aluminum plate. In order to reach the state of H16, the metal is strain hardened to about 3 / 4 of the strength between annealing (o) and full hardening (h28).

1060-h28 aluminum plate is usually tempered only by z-strength produced by strain hardening.

1060-h22 aluminum sheet metal is strain hardened and then partially annealed, and its strength is about one quarter between annealing (o) and full hardening (h28).

1060-h26 aluminum plate in order to reach this temperature, the metal is strain hardened and then partially annealed, and its strength is about 3/4 between annealing (o) and full hardness (h28).

The 1060-h28 aluminum plate is usually tempered with Z strength by strain hardening followed by partial annealing. It is closely related to h28.

1060-o aluminum plate is provided in annealed (o) state. Compared with other variants of 1060 Aluminum, it has z-high ductility.

1060 Aluminum plate product introduction:

1060 Aluminum plate processing strengthening, also known as cold work hardening, is the cold deformation treatment of metal materials below the recrystallization temperature, such as forging, calendering, stretching, stretching, etc. During cold deformation, the internal dislocation of metal is dense?? The degree increases, and intertwines with each other to form a cell structure that hinders the movement of dislocations. The larger the deformation degree, the more serious the dislocation entanglement, the greater the deformation resistance and the higher the strength. The degree of strengthening after cold deformation varies with the degree of deformation, the deformation temperature of 1060 pure aluminum plate, and the properties of the material itself. When the same material is cold deformed at the same temperature, the greater the deformation degree, the higher the strength and the lower the plasticity.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible