1060 Series Aluminium Plate Sheet

Materials: 1050, 1060, 1100, 3003, 5052, 5083, 6061, 8011, etc

Thickness: 0.3mm-6mm

Width 900mm --- 1950mm

1060 Aluminum plate belongs to industrial pure aluminum, which has high plasticity, corrosion resistance, conductivity and thermal conductivity, but it has low strength, can not be strengthened by heat treatment and poor machinability; It can be gas welding, hydrogen atom welding and contact welding, and is not easy to braze; Easy to bear all kinds of pressure processing, drawing and bending.

Basic Instruction

Aluminum plate is substantially carried out in merchandise with low power requirements. Products are generally carried out in signboards, billboards, constructing look ornament, bus body, wall ornament of high-upward push homes and factories, kitchen sink, lamp holder, fan blade, digital parts, chemical instruments, sheet metallic processing parts, deep drawing or spinning concave utensils, welding parts, warmness exchangers, clock floor and disk floor, nameplates, kitchenware, decorations, reflective appliances, etc.

Specification

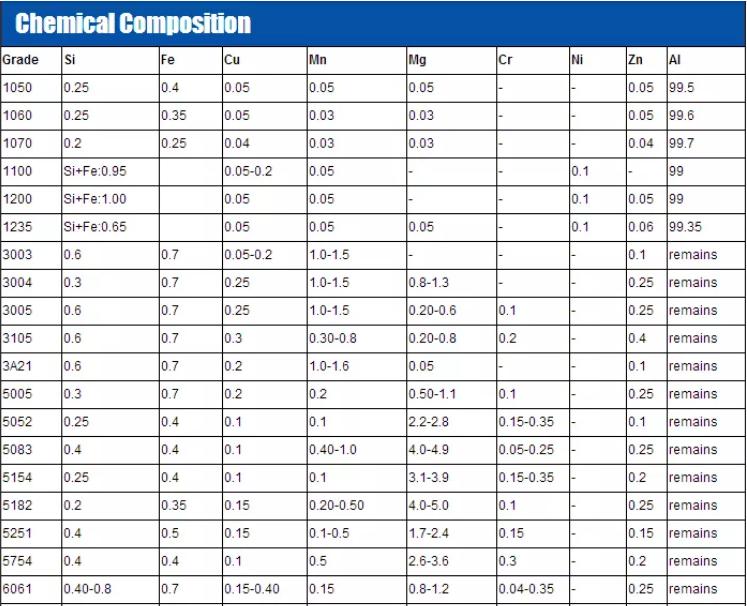

AI(%) | Si(%) | Cu(%) | Mg(%) | Zn(%) | Mn(%) | Ti(%) | V(%) | Fe(%) |

99,60 | 0.25 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.05 | 0.350 |

Component

Material name: aluminum and aluminum alloy extruded bar (≤ 150mm, h112, T6, O state) standard: GB / T characteristics and scope of application: ① 5052 is an Al Mg alloy, which is widely used, especially in the construction industry. It is the most promising alloy. Good corrosion resistance, excellent weldability, good cold workability and medium strength. The main alloy element of 5052 is magnesium, which has good forming and processing performance, corrosion resistance, weldability and medium strength. It is used to manufacture aircraft fuel tank, oil pipe, sheet metal parts of traffic vehicles and ships, instruments, street lamp supports and rivets, hardware products, electrical shell, etc. ② Al Mn alloy is the most widely used antirust aluminum. This alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment, good plasticity in semi cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing. It is mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium, such as mailbox, gasoline or lubricating oil conduit, various liquid containers and other low load parts made by deep drawing: wire rod is used to make rivets. Guangyue metal 5052 aluminum plate

1. Cracks, corrosion spots and traces of nitrate are not allowed on the surface.

2. Peeling, bubbles, surface roughness and local mechanical damage with the depth not exceeding 8% of the nominal wall thickness of the defect location are allowed on the surface, but the maximum depth of the defect shall not exceed 0.5mm, and the total area of the defect shall not exceed 5% of the total area of the plate.

3. The supplier is allowed to polish the profile longitudinally until the surface is smooth.

4. The supplier has its own requirements and other requirements

Related Products

Related News

Submitted successfully

We will contact you as soon as possible