Características técnicas da linha de produção:1. CNC é totalmente automático. esta linha de produção começa a partir de desenrolar materiais enrolados para a conclusão de blanking de todo o rolo de materiais. não há necessidade de contato manual com quaisquer materiais e nenhuma necessidade de qualquer ajuste, o que elimina fundamentalmente o perigo oculto da segurança da produção e qualidade do produto de perfuração comum.2.

Contact Now

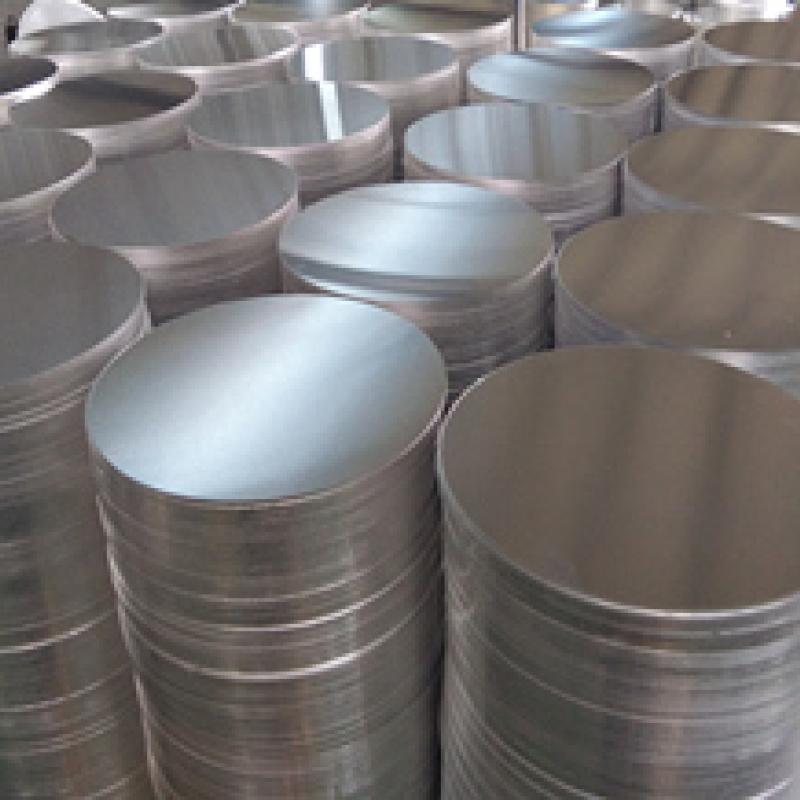

Aluminum wafers are mainly used in kitchenware production, sign making and other industries. The commonly used thickness is 1.0mm aluminum wafers and 1.2mm aluminum wafers. Among them, the kitchenware production industry has a large demand for aluminum wafers, especially in foreign countries. Because of its safety, lightness and easy processing, aluminum kitchenware products are more and more favored by customers. The 0.8mm aluminum wafers produced by Chaoyang Aluminum Co., Ltd. are hot rolled and cold rolled, of which 1060 Aluminum wafers and 3003 aluminum wafers are very popular.

Contact Now

Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pressure of press (KN): 1250160020002500Alloy stateMost of them are 1 series, 3 series, 5 series, 6 series and 8 series.The status is O, h, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pres

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate product of pure aluminum or aluminum alloy via stress processing (shearing or sawing) to achieve square pass segment and uniform thickness internationally, it's miles standard to name aluminum substances with thickness of greater than 0.2mm, a whole lot much less than 500mm, width of extra than 200mm and period of a whole lot much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of a whole lot much less than 200mm as row or strip (of path, with the improvement of large mach

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is long-hooked up at the surface. The anodized aluminum plate improves its hardness and positioned on resistance, suitable warm temperature resistance, the melting factor of difficult anodized movie is as loads as 2320k, extremely good insulation, breakdown voltage resistance is as loads as 2000V, complements the corrosion resistance, and does now no longer corrode in high-strength salt spray for hundreds of hours.

Contact Now

Our company mainly engages in deep processing of aluminum sheet. Our leading products are aluminum plate, aluminum strip, aluminum foil, aluminum volume, aluminum pole, aluminum scrap, color-painted aluminum plate and volume, decorative pattern aluminum plate and volume and aluminum sheet circle. We have international advanced producing equipments as caster, hot mill, cold-rolling mill, etc. Our company has 100,000 tons’ annual production capacity. Our main products series are series 1, series 2, series 3, series 5, series 6 and series 8.

Contact Now

The representative 1000 series aluminum plate is also called pure aluminum plate. Among all the series, 1000 series belongs to the series with the largest aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively low. It is the most commonly used series in the conventional industry. Most of the 1050 and 1060 series are in circulation in the market. The minimum aluminum content of the 1000 series aluminum plate is determined according to the last two Arabic numerals.

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveler, feeder, swing unit, special closed single point mechanical press, rapid die changing device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical features of production line:1. Numerical control is fully automatic. The production line does not need any manual contact with any labor and materials from the uncoiling of the coil to the completion of the blanking of the whole coil of materials.

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate made of pure aluminum or aluminum alloy through strain processing (shearing or sawing) to achieve rectangular cross section and uniform thickness the world over, it is customary to call aluminum materials with thickness of more than 0.2mm, much less than 500mm, width of extra than 200mm and length of much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of much less than 200mm as row or strip (of route, with the development of huge system, there are extra rows wi

Contact Now

classificationThe grade of aluminum alloy is representative. The following is an example of 7075T651 aluminum plate grade. The first 7 represents the aluminum and aluminum alloy group - aluminum zinc magnesium alloy. Aluminum and aluminum alloy groups are divided into nine categories.

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent.

Contact Now

FeaturesCorrosion resistanceThe density of aluminum profile is handiest 2.7g/cm3, about 1 / 3 of that of steel, copper or brass (7.83g/cm3 and 8.93g/cm3 respectively). Aluminum shows super corrosion resistance beneathneath most environmental conditions, including air, water (or brine), petrochemical and masses of chemical systems.conductivityAluminum profile is regularly decided on due to its superb conductivity. On the idea of same weight, the conductivity of aluminum is near 1 / 2 of that of copper.Installation lap diagramSpecification

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is prepared 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, similarly to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contact Now

FeaturesCorrosion resistanceThe density of aluminum profile is simplest 2.7g/cm3, approximately 1 / three of that of steel, copper or brass (7.83g/cm3 and 8.93g/cm3 respectively). Aluminum suggests superb corrosion resistance beneathneath maximum environmental conditions, inclusive of air, water (or brine), petrochemical and plenty of chemical systems.conductivityAluminum profile is regularly decided on due to its superb conductivity. On the idea of same weight, the conductivity of aluminum is near 1 / 2 of that of copper.Installation lap diagramSpecification

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.Installation lap diagramSpecification

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles cannot spontaneously ignite, which is important for applications involving handling or contacting flammable and explosive materials.SpecificationInstallation lap diagr

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles cannot spontaneously ignite, which is important for applications involving handling or contacting flammable and explosive materials.SpecificationInstallation lap diagr

Contact Now

High quality aluminum skin,Cheap aluminum skin,Aluminum leather factory.Technical parameters of production line:Coil width (mm) : 500-1250800-14001000-1600Coil thickness (mm) : 0.4-3.0, 1.0-6.0Volume weight (kg) : 8000010000Cutting diameter (mm) : 85-660, 85-750100-900Blanking time (SPM) : 40-55Nominal pressure of press (kN) : 1250160020002500Alloy stateMost of them are 1, 3, 5, 6 and 8.The status is O or H.

Contact Now

Aluminum manufacturer,Cheap aluminum sheet,Good quality aluminum plate3003 aluminum plate used for oil tank, gas or oil duct, and other various liquid containers made of deep drawing parts: small load wire used for rivet, kitchen utensils and appliances, food and chemical products processing and storage device, the transportation of liquid product tank, tank, with thin plate processing all kinds of pressure vessel and pipeline General items, heat sink, makeup, copy machine roller, ship material.

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate crafted from herbal aluminum or aluminum alloy thru stress processing (shearing or sawing) to collect rectangular flow section and uniform thickness the world over, it's far ordinary to call aluminum materials with thickness of extra than 0.2mm, lots plenty much less than 500mm, width of greater than 200mm and period of lots plenty much less than 16m as aluminum plate or aluminum sheet, plenty much less than 0.2mm as aluminum foil and width of lots plenty much less than 200mm as row or strip (of route, with the develo

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate product of pure aluminum or aluminum alloy via stress processing (shearing or sawing) to achieve square pass segment and uniform thickness internationally, it's miles standard to name aluminum substances with thickness of greater than 0.2mm, a whole lot much less than 500mm, width of extra than 200mm and period of a whole lot much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of a whole lot much less than 200mm as row or strip (of path, with the improvement of large mach

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now

The selection of thermal insulation aluminum coil should pay attention to cost performance:1. We should not only pay attention to the price when purchasing thermal insulation aluminum coils, but also pay attention to the products based on the price. After all, the price is the same as the goods. We must pay attention to the products whose price is too low to avoid big losses due to greed. Of course, under the same circumstances, we should look at the price, and choose the cost-effective enterprise is our final choice.2.

Contact Now

Al Mn series alloy is one of the most widely used antirust aluminum. This alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, and cannot be strengthened by heat treatment. It has good plasticity during semi cold work hardening, low plasticity during cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing.

Contact Now