Electrolytic zinc cathode plateEnergy saving electrolytic zinc cathode plate is composed of aluminum beam, aluminum plate and conductive clamp.

Contact Now

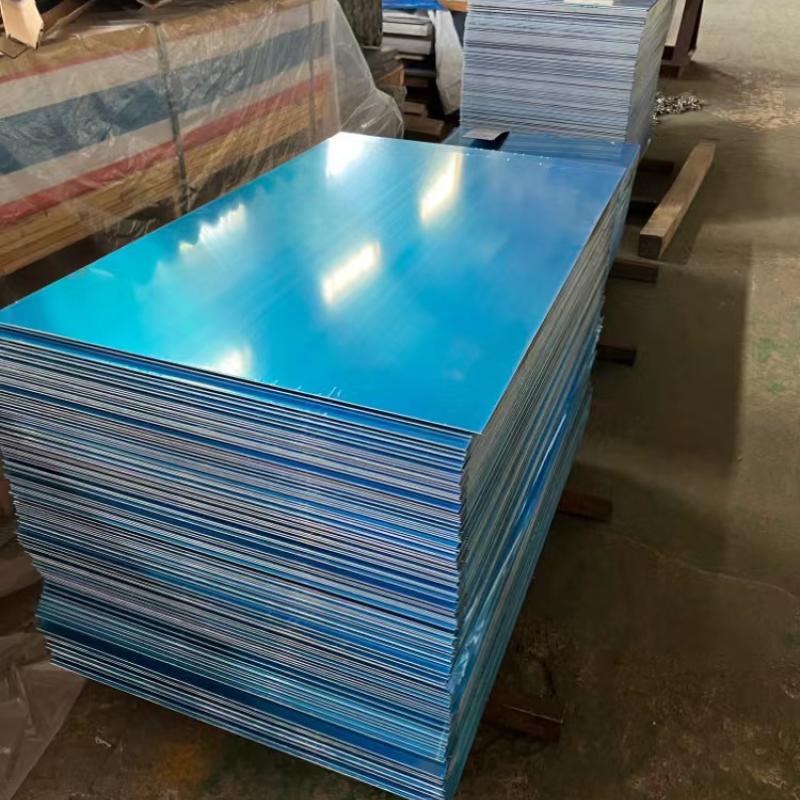

Aluminum plate is mainly used for lighting, solar reflection sheet, building appearance, ceiling, furniture, cabinet, elevator, sign, nameplate, luggage, interior and exterior decoration of automobile, refrigerator, microwave oven, audio equipment, aerospace and military aspects.

Contact Now

Brushed aluminum plate: the manufacturing process of repeatedly scraping aluminum plates out of lines with sandpaper. The main process flow is divided into three parts: deaster, sand mill and water washing.

Contact Now

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

The company's prompt delivery, high quality and low price, service and thoughtful.

Contact Now

Aluminum plates are generally divided into the following two types:1.

Contact Now

1. Pure aluminum plate: Material: 1050 / 1060 / 1070 / 1100 thickness: 0.1-500mm width: 10-2200mm2. Alloy aluminum plate: Material: 3003 / 5052 / 5754 / 5083 / 6061 / 6063 / 6082 / 7075 / 8011 thickness: 0.2-500mm width: 800-2800mm3. Curtain wall leveling aluminum plate: Material: 1060 / 1100, thickness: 0.95, 1.35, 1.5, 1.85, 2.0, 2.35, 2.5, 2.7, 2.85, 3.0mm, width: 800-1500mm2、 Aluminum coil: | aluminum foilMaterial: 1060 / 1100 / 8011 / 3003 / 3004 / 5052 thickness: 0.1-10mm width: 600-2000mm1.

Contact Now

Embossed aluminum plate manufacturer,Aluminum manufacturer,High quality aluminum plate manufacturers.Sales material 1 series, 3 series, 4 series, 5 series, 6 series, 8 series aluminum alloy and other 6 specifications series aluminum plate size standard, the main products are CTP/PS plate base, electrolytic capacitor aluminum foil, single zero foil, double zero foil blank, electronic foil, alloy material, deep punching material, brazing plate, thick plate.

Contact Now

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contact Now

How to judge the quality of aluminum brick 1. Observe whether there are multiple scratches on the surface of the aluminum corrugated plate. Aluminum ceramic tile belongs to mechanical processing, which will inevitably lead to some scratches and scratches, but if it is too much, the beauty will be affected. Friends who have high requirements for the surface of aluminum ceramic tiles can also ask the manufacturer to carry out film coating processing in advance. 2.

Contact Now

Aluminum manufacturer,Cheap aluminum sheet,Good quality aluminum plate3003 aluminum plate used for oil tank, gas or oil duct, and other various liquid containers made of deep drawing parts: small load wire used for rivet, kitchen utensils and appliances, food and chemical products processing and storage device, the transportation of liquid product tank, tank, with thin plate processing all kinds of pressure vessel and pipeline General items, heat sink, makeup, copy machine roller, ship material.

Contact Now

Aluminum sheet supplier,Aluminum manufacturer,Aluminium sheet manufacturer.1060 aluminum plate belongs to industrial pure aluminum, has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not be strengthened, cutting is not good; Can be gas welding, hydrogen welding and contact welding, not easy to braze; Easy to withstand a variety of pressure processing and extension, bending.1060 aluminum plate is widely used in low strength requirements of products.

Contact Now

Embossed aluminum foil manufacturer,Aluminum coil manufacturer,Aluminum manufacturerSmoke foilAlloy state :1235-O, 8079-OTypical thickness :0.006~0.007Processing method: composite paper, coloring, printing, etcEnd use: Cigarette packaging after lining, printing or painting.Flexible packaging foilAlloy state :8079-O, 1235-OTypical thickness :0.006~0.009Processing mode: composite paper, plastic film embossing, printing, etcEnd use: confectionery, milk and milk products, powder food, beverage, tea, bread and all kinds of small food, etc.Card paper screenAlloy state :1235-O, 8079-O Typical thickne

Contact Now

The selection of thermal insulation aluminum coil should pay attention to cost performance:1. We should not only pay attention to the price when purchasing thermal insulation aluminum coils, but also pay attention to the products based on the price. After all, the price is the same as the goods. We must pay attention to the products whose price is too low to avoid big losses due to greed. Of course, under the same circumstances, we should look at the price, and choose the cost-effective enterprise is our final choice.2.

Contact Now

Basic Instruction1060 aluminum plate is broadly used in products with low electricity necessities.

Contact Now

1060 Aluminum plate application1060 Aluminum plate products are commonly used for signs, billboards, exterior decoration of buildings, bus bodies, wall decoration of high-rise buildings and factories, kitchen sinks, lamp holders, fan blades, electronic parts, chemical equipment, mechanical parts, plate deep drawing or rotating concave parts, welding parts, heat exchangers, clock faces and plates, plates, kitchen utensils, ornaments, reflective equipment, etcIntroduction to 1060 series aluminum plate1060-h24 aluminum plate is a kind of 1060 Aluminum plate.

Contact Now

Also we would like to supply you some following more details about our part materials:1100 Aluminum SheetLow strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. It is unmatched by any other commercial aluminum alloy in workability. Readily to welding, brazing, and soldering. Machinability is poor and tends to be “gummy”. Non-heat treatable. Typical applicationsinclude chemical storage, processing equipment, kitchen utensils, and general sheet metal work. 3003 Aluminum SheetApprox.

Contact Now

Corrugated aluminum plate, also known as aluminum tile. It is one of the commonly used products in architecture. At present, there is a trend to replace stainless steel and iron plate.Advantages of corrugated aluminum plate:First of all, since the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of aluminum tile per square meter is less than 1 / 3 of that of stainless steel, which greatly reduces the cost of the enterprise and reduces the pressure of the bracket.Secondly, aluminum has good anti rust effect.

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7g /, about 1 / 3 of that of iron or copper. Aluminum and aluminum alloy have high strength. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is second only to silver, copper and gold. 3.

Contact Now

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

Basic Instruction1060 aluminum plate is broadly applied in products with low electricity necessities.

Contact Now

Basic InstructionAluminum plate is significantly applied in products with low strength requirements.

Contact Now

Application scopeAnodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.Advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed.

Contact Now