First of all, aluminum is light in weight and has strong corrosion resistance, which are the most significant characteristics of aluminum wafers. Because of its small density and light weight, it is widely used in aviation, automobile, ship and other transportation manufacturing industries. In addition, a large number of aluminum discs, aluminum metals and aluminum alloys are also used in high-technology industries such as spaceships and artificial satellites.Secondly, it has excellent conductivity.

Contact Now

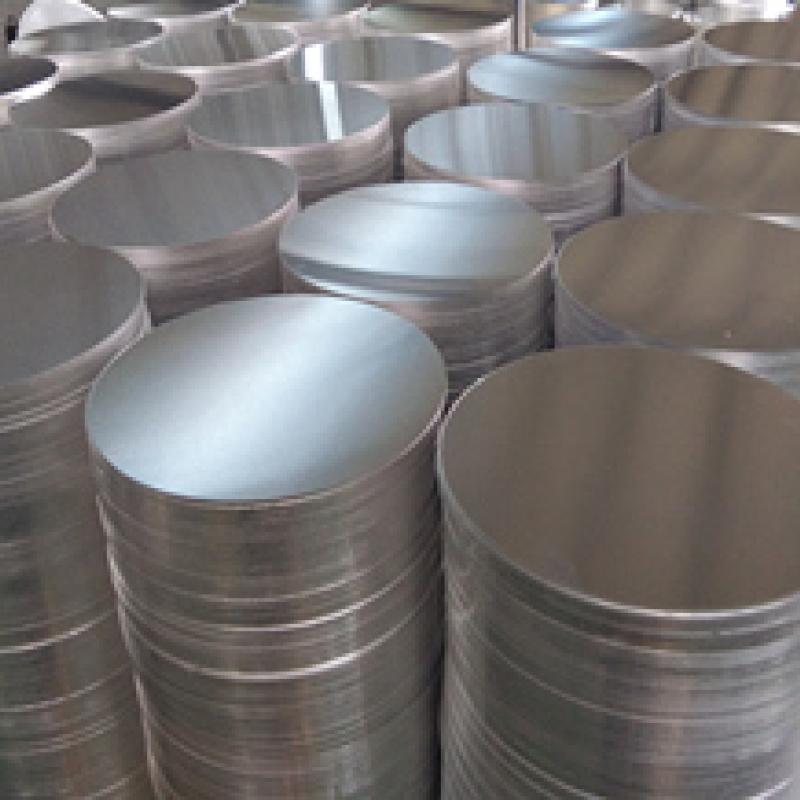

Chengye plate aluminum wafer has some advantages:1. Excellent elongation and tensile strength;2. Good processing performance, high stamping and stretch forming performance;3. Gas welding, hydrogen welding, resistance welding and brazing;4. High plasticity, conductivity and thermal conductivity;5.

Contact Now

Aluminum wafers are very common in our life. Aluminum wafers can be found in can sealing, non stick pot bottom, traffic signs, lamp covers, and so on. In addition, aluminum wafers are also frequently used in mechanical manufacturing, automobile and other industrial fields. Therefore, when purchasing aluminum wafers, the primary consideration is the use. The use determines whether to purchase hot rolled or cast rolled materials.

Contact Now

The surface of the aluminum wafer has high-intensity reflectance, which can reflect radiation, visible light and so on, making the surface smooth and playing a good decorative role. Moreover, the surface of aluminum material with good reflectivity is smooth. As a cooker, it will have excellent workmanship and strong aesthetic feeling, which can improve the taste of offending, and the high reflectivity can reduce the damage to the product, which can well extend the service life of the product. 1.

Contact Now

Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pressure of press (KN): 1250160020002500Alloy stateMost of them are 1 series, 3 series, 5 series, 6 series and 8 series.The status is O, h, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pres

Contact Now

"Aluminum wafers aluminum wafers are widely used in electronics, daily chemicals, medicine, culture and education, and auto parts. Electrical appliances, thermal insulation, machinery manufacturing, automobile, aerospace, military industry, mold, construction, printing and other industries. Such as kitchen utensils such as non stick pots, pressure pans, and hardware supplies such as lampshades, water heater shells, and stretching tanks, it is one of the largest aluminum alloy plate and strip deep processing products."

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now

Aluminum wafers are widely used in electronics, daily chemicals, medicine, culture and education and auto parts. Electrical appliances, thermal insulation, machinery manufacturing, automobile, aerospace, military industry, mold, construction, printing and other industries. Such as kitchen utensils such as non stick pots, pressure pans, etc., and hardware supplies such as lampshades, water heater shells, stretching tanks, etc., it is one of the largest aluminum alloy plate and strip deep processing products.

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical characteristics of the production line:1. CNC is fully automatic. This production line starts from uncoiling of coiled materials to the completion of blanking of the whole roll of materials.

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is prepared 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, similarly to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate made from natural aluminum or aluminum alloy via pressure processing (shearing or sawing) to acquire square move phase and uniform thickness the sector over, it's miles normal to name aluminum substances with thickness of greater than 0.2mm, plenty much less than 500mm, width of more than 200mm and duration of plenty much less than 16m as aluminum plate or aluminum sheet, much less than 0.2mm as aluminum foil and width of plenty much less than 200mm as row or strip (of route, with the improvement of big system, there

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.Installation lap diagramSpecification

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate product of pure aluminum or aluminum alloy via stress processing (shearing or sawing) to achieve square pass segment and uniform thickness internationally, it's miles standard to name aluminum substances with thickness of greater than 0.2mm, a whole lot much less than 500mm, width of extra than 200mm and period of a whole lot much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of a whole lot much less than 200mm as row or strip (of path, with the improvement of large mach

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles cannot spontaneously ignite, which is important for applications involving handling or contacting flammable and explosive materials.SpecificationInstallation lap diagr

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles cannot spontaneously ignite, which is important for applications involving handling or contacting flammable and explosive materials.SpecificationInstallation lap diagr

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is set 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, in addition to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate product of pure aluminum or aluminum alloy via stress processing (shearing or sawing) to achieve square pass segment and uniform thickness internationally, it's miles standard to name aluminum substances with thickness of greater than 0.2mm, a whole lot much less than 500mm, width of extra than 200mm and period of a whole lot much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of a whole lot much less than 200mm as row or strip (of path, with the improvement of large mach

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate made of pure aluminum or aluminum alloy through strain processing (shearing or sawing) to achieve rectangular cross section and uniform thickness the world over, it is customary to call aluminum materials with thickness of more than 0.2mm, much less than 500mm, width of extra than 200mm and length of much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of much less than 200mm as row or strip (of route, with the development of huge system, there are extra rows with a most width

Contact Now

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contact Now

Aluminum wafers are mainly used in kitchenware production, sign making and other industries. The commonly used thickness is 1.0mm aluminum wafers and 1.2mm aluminum wafers. Among them, the kitchenware production industry has a large demand for aluminum wafers, especially in foreign countries. Because of its safety, lightness and easy processing, aluminum kitchenware products are more and more favored by customers. The 0.8mm aluminum wafers produced by Chaoyang Aluminum Co., Ltd. are hot rolled and cold rolled, of which 1060 Aluminum wafers and 3003 aluminum wafers are very popular.

Contact Now

Basic InstructionAluminum coil is extensively utilized in electronics, packaging, construction, equipment and so on. What are the makes use of of aluminum coils? What are the classifications of aluminum coils? Aluminum coil producers solution your questions and remedy your doubts. We are a complete employer specializing withinside the production, income and transportation of non-ferrous metals.

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.Installation lap diagramSpecification

Contact Now

Basic InstructionAluminum plate refers to the square aluminum plate crafted from natural aluminum or aluminum alloy thru pressure processing (shearing or sawing) to build up square byskip phase and uniform thickness internationally.primary merchandise are aluminum and aluminum alloy plate, aluminum coil, aluminum strip, aluminum foil, aluminum rod, aluminum pipe, aluminum wire aluminum ingots and unique merchandise have handed the 2000 model of iso9001 high-quality device certification. aluminum foil and incredible merchandise have received the select out of u . s .

Contact Now

Aluminum sheet is one of all aluminum products, which is called aluminum roll or aluminum strip in professional terms. Aluminum sheet is a kind of non-ferrous metal with high aluminum content. It is often used in various large chemical plants, power plants, pharmaceutical plants, oil refineries and other enterprises. It is one of the building materials for thermal insulation and corrosion protection. Aluminum sheet is the embodiment of aluminum ingot. It is repeatedly processed into rough cast roll through massive aluminum ingot.

Contact Now