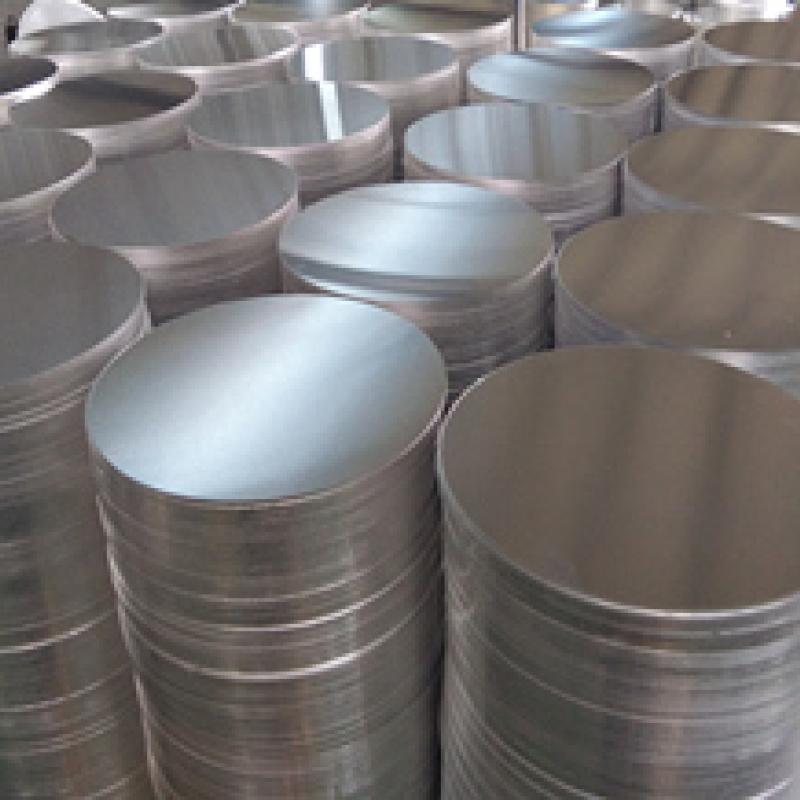

Aluminum wafers are mainly used in kitchenware production, sign making and other industries. The commonly used thickness is 1.0mm aluminum wafers and 1.2mm aluminum wafers. Among them, the kitchenware production industry has a large demand for aluminum wafers, especially in foreign countries. Because of its safety, lightness and easy processing, aluminum kitchenware products are more and more favored by customers. The 0.8mm aluminum wafers produced by Chaoyang Aluminum Co., Ltd. are hot rolled and cold rolled, of which 1060 Aluminum wafers and 3003 aluminum wafers are very popular.

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical characteristics of the production line:1. CNC is fully automatic. This production line starts from uncoiling of coiled materials to the completion of blanking of the whole roll of materials.

Contact Now

Chengye plate aluminum wafer has some advantages:1. Excellent elongation and tensile strength;2. Good processing performance, high stamping and stretch forming performance;3. Gas welding, hydrogen welding, resistance welding and brazing;4. High plasticity, conductivity and thermal conductivity;5.

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate made from natural aluminum or aluminum alloy via pressure processing (shearing or sawing) to acquire square move phase and uniform thickness the sector over, it's miles normal to name aluminum substances with thickness of greater than 0.2mm, plenty much less than 500mm, width of more than 200mm and duration of plenty much less than 16m as aluminum plate or aluminum sheet, much less than 0.2mm as aluminum foil and width of plenty much less than 200mm as row or strip (of route, with the improvement of big system, there

Contact Now

The surface of the aluminum wafer has high-intensity reflectance, which can reflect radiation, visible light and so on, making the surface smooth and playing a good decorative role. Moreover, the surface of aluminum material with good reflectivity is smooth. As a cooker, it will have excellent workmanship and strong aesthetic feeling, which can improve the taste of offending, and the high reflectivity can reduce the damage to the product, which can well extend the service life of the product. 1.

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate made of pure aluminum or aluminum alloy through strain processing (shearing or sawing) to achieve rectangular cross section and uniform thickness the world over, it is customary to call aluminum materials with thickness of more than 0.2mm, much less than 500mm, width of extra than 200mm and length of much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of much less than 200mm as row or strip (of route, with the development of huge system, there are extra rows wi

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate made of pure aluminum or aluminum alloy through strain processing (shearing or sawing) to achieve rectangular cross section and uniform thickness the world over, it is customary to call aluminum materials with thickness of more than 0.2mm, much less than 500mm, width of extra than 200mm and length of much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of much less than 200mm as row or strip (of route, with the development of huge system, there are extra rows with a most width

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate product of pure aluminum or aluminum alloy via stress processing (shearing or sawing) to achieve square pass segment and uniform thickness internationally, it's miles standard to name aluminum substances with thickness of greater than 0.2mm, a whole lot much less than 500mm, width of extra than 200mm and period of a whole lot much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of a whole lot much less than 200mm as row or strip (of path, with the improvement of large mach

Contact Now

Basic InstructionAluminum plate refers back to the square aluminum plate product of pure aluminum or aluminum alloy via stress processing (shearing or sawing) to achieve square pass segment and uniform thickness internationally, it's miles standard to name aluminum substances with thickness of greater than 0.2mm, a whole lot much less than 500mm, width of extra than 200mm and period of a whole lot much less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of a whole lot much less than 200mm as row or strip (of path, with the improvement of large mach

Contact Now

Thermal insulation aluminum coil has beautiful, durable and practical functionsThe thermal insulation data can be closely connected with the decoration data, so the problem that the thermal insulation data can not be closely connected with the decoration data is solved After contact, it is not easy to fall or loosen, and enhances the wind pressure resistance of the decoration surface data The decoration surface is also diversified in color, and can be processed into various plate shapes, which can better show the characteristics of construction and decoration.

Contact Now

Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pressure of press (KN): 1250160020002500Alloy stateMost of them are 1 series, 3 series, 5 series, 6 series and 8 series.The status is O, h, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pres

Contact Now

First of all, aluminum is light in weight and has strong corrosion resistance, which are the most significant characteristics of aluminum wafers. Because of its small density and light weight, it is widely used in aviation, automobile, ship and other transportation manufacturing industries. In addition, a large number of aluminum discs, aluminum metals and aluminum alloys are also used in high-technology industries such as spaceships and artificial satellites.Secondly, it has excellent conductivity.

Contact Now

1. Thermal insulation aluminum coil has beautiful and durable functionsThe thermal insulation data can be closely linked with the decoration surface data, so the problem that the thermal insulation data cannot be closely linked with the decoration surface data has been solved. It is not easy to drop or loosen after contact, and the wind pressure resistance of the decoration surface data has been enhanced. The decoration surface has diversified colors, and can be processed into a forest of plates, which can better represent the characteristics of construction and decoration2.

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate crafted from herbal aluminum or aluminum alloy thru stress processing (shearing or sawing) to collect rectangular flow section and uniform thickness the world over, it's far ordinary to call aluminum materials with thickness of extra than 0.2mm, lots plenty much less than 500mm, width of greater than 200mm and period of lots plenty much less than 16m as aluminum plate or aluminum sheet, plenty much less than 0.2mm as aluminum foil and width of lots plenty much less than 200mm as row or strip (of route,

Contact Now

How to judge the quality of aluminum brick 1. Observe whether there are multiple scratches on the surface of the aluminum corrugated plate. Aluminum ceramic tile belongs to mechanical processing, which will inevitably lead to some scratches and scratches, but if it is too much, the beauty will be affected. Friends who have high requirements for the surface of aluminum ceramic tiles can also ask the manufacturer to carry out film coating processing in advance. 2.

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate crafted from herbal aluminum or aluminum alloy thru stress processing (shearing or sawing) to collect rectangular flow section and uniform thickness the world over, it's far ordinary to call aluminum materials with thickness of extra than 0.2mm, lots plenty much less than 500mm, width of greater than 200mm and period of lots plenty much less than 16m as aluminum plate or aluminum sheet, plenty much less than 0.2mm as aluminum foil and width of lots plenty much less than 200mm as row or strip (of route, with the develo

Contact Now

Brushed aluminum plate: the manufacturing process of repeatedly scraping aluminum plates out of lines with sandpaper. The main process flow is divided into three parts: deaster, sand mill and water washing.

Contact Now

Decoration Aluminum tiles (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) have a variety of colors and shapes, beautiful appearance, bright light color, rich aluminum color and anti fading.High recovery value Aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) has high use value after recycling due to its corrosion resistance, and the recovery rate is more than 80%.1.

Contact Now

The company's prompt delivery, high quality and low price, service and thoughtful.

Contact Now

Aluminum sheet supplier,Aluminum manufacturer,Aluminium sheet manufacturer.1060 aluminum plate belongs to industrial pure aluminum, has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not be strengthened, cutting is not good; Can be gas welding, hydrogen welding and contact welding, not easy to braze; Easy to withstand a variety of pressure processing and extension, bending.1060 aluminum plate is widely used in low strength requirements of products.

Contact Now

Aluminum plates are generally divided into the following two types:1.

Contact Now

Embossed aluminum plate manufacturer,Aluminum manufacturer,High quality aluminum plate manufacturers.Sales material 1 series, 3 series, 4 series, 5 series, 6 series, 8 series aluminum alloy and other 6 specifications series aluminum plate size standard, the main products are CTP/PS plate base, electrolytic capacitor aluminum foil, single zero foil, double zero foil blank, electronic foil, alloy material, deep punching material, brazing plate, thick plate.

Contact Now

The company's prompt delivery, high quality and low price, service and thoughtful. the special size can be customized according to customer requirements processing, complete specifications, the lowest price, factory direct sales, quality assurance, delivery: seven days or so.Production site: Shandong province Pingyin County village north hole aluminum plantPhone: 15064183919Biography: 0531-87886769Web site: www.sdalcoa.com

Contact Now