Aluminum plates are generally divided into the following two types:1.

Contact Now

advantage1. Aluminum tiles (corrugated aluminum plates, corrugated aluminum plates, profiled aluminum plates) are light in weight, and their density is only one third of that of steel. For the same thickness, the price per square meter is calculated, and the price of steel and aluminum is almost the same.2. Corrugated aluminum plates (aluminum tiles, corrugated aluminum plates, profiled aluminum plates) are easy to process and form, and the construction is convenient and fast, greatly reducing the construction strength.3.

Contact Now

Aluminum plates are generally divided into the following two types:1.

Contact Now

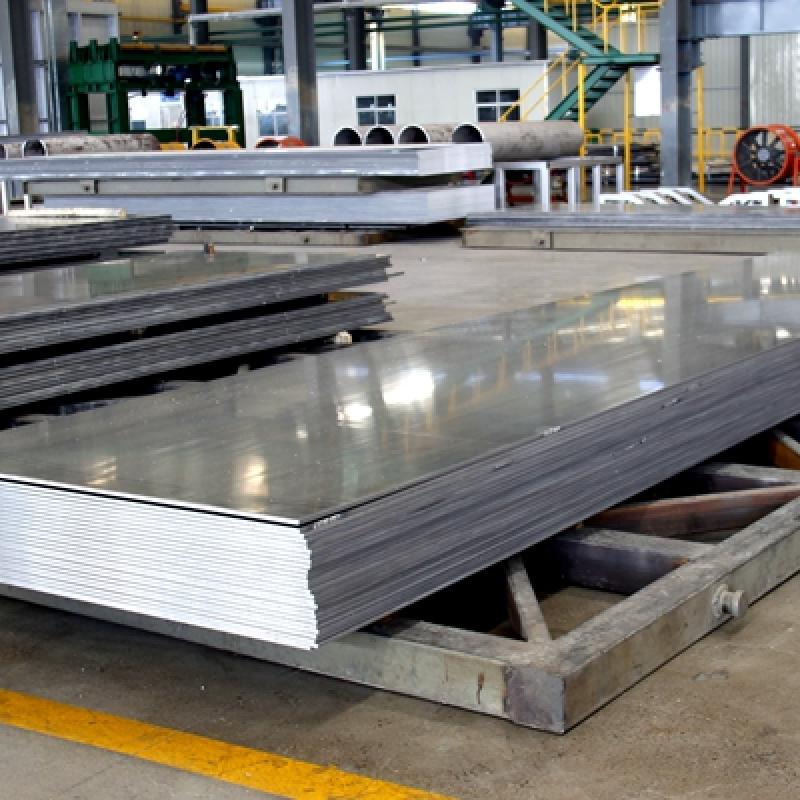

Aluminum plates refer to rectangular plates rolled from aluminum ingots, which are divided into pure aluminum plates, alloy aluminum plates, thin aluminum plates, medium thick aluminum plates, and patterned aluminum plates1.

Contact Now

Aluminum plates are generally divided into the following two types:1.

Contact Now

1060 Aluminum plate application1060 Aluminum plate products are commonly used for signs, billboards, exterior decoration of buildings, bus bodies, wall decoration of high-rise buildings and factories, kitchen sinks, lamp holders, fan blades, electronic parts, chemical equipment, mechanical parts, plate deep drawing or rotating concave parts, welding parts, heat exchangers, clock faces and plates, plates, kitchen utensils, ornaments, reflective equipment, etcIntroduction to 1060 series aluminum plate1060-h24 aluminum plate is a kind of 1060 Aluminum plate.

Contact Now

Patterned aluminum plate is a kind of very common aluminum plate, which can be used for decoration in some places and anti-skid in some places. Due to the special treatment process of aluminum plate, in order to protect the aluminum plate from playing a normal role and not affecting the appearance, it should be maintained correctly. Then, how to clean the patterned aluminum plate? How to clean the patterned aluminum plate?In addition to the application of acidic substances on the reaction plate, it is also easy to neutralize this kind of substances on the reaction plate.

Contact Now

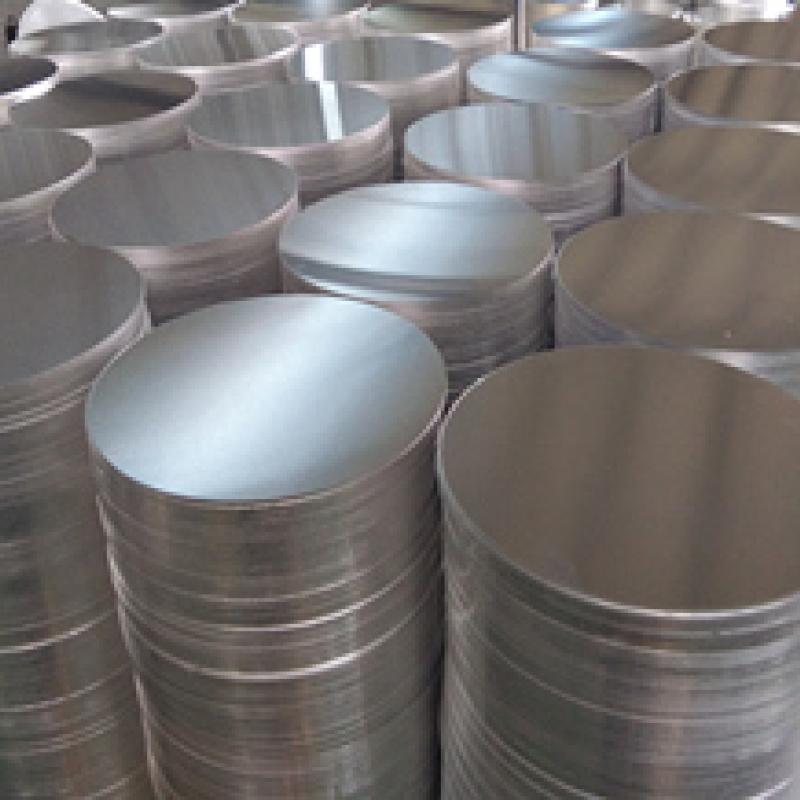

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now

Brushed aluminum plate: the manufacturing process of repeatedly scraping aluminum plates out of lines with sandpaper. The main process flow is divided into three parts: deaster, sand mill and water washing.

Contact Now

The patterned aluminum plate is a common material at present, which can be used in many places, including home decoration and household appliances. The wide application of aluminum plate is inseparable from its characteristics. There are many kinds of aluminum plates in our daily life. What are the advantages of patterned aluminum plates? The following five points can be summarized.1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high.

Contact Now

Shandong Jincheng Aluminum Co., Ltd. produces and processes various aluminum profiles such as aluminum plates, aluminum coils, aluminum strips, aluminum foils, aluminum wires, aluminum beans, aluminum particles, etc.

Contact Now

5052 is an aluminum magnesium alloy, which is widely used, especially in the construction industry. This is a promising alloy. Good corrosion resistance, excellent weldability, good cold workability and medium strength. The main alloy element of 5052 is magnesium, which has good formability, corrosion resistance, weldability and medium strength. It is used to manufacture aircraft fuel tanks, fuel pipes, metal plates, instruments, street lamp supports, rivets, hardware products, electrical enclosures, etc. of vehicles and ships.

Contact Now

Patterned aluminum plate is mainly divided into five rib patterned aluminum plate, pointer patterned aluminum plate, orange peel patterned aluminum plate and bean patterned aluminum plate.The production process of patterned aluminum plate is embossed on the basis of aluminum plate to achieve beautiful effect. Patterned aluminum plate has anti-skid effect According to the different patterns, the pattern aluminum plate can be divided into anti-skid aluminum plate and aesthetic aluminum plate. The following series will explain these two kinds of aluminum plates.1、 Aesthetic.

Contact Now

1. Thermal insulation aluminum coil has beautiful and durable functionsThe thermal insulation data can be closely linked with the decoration surface data, so the problem that the thermal insulation data cannot be closely linked with the decoration surface data has been solved. It is not easy to drop or loosen after contact, and the wind pressure resistance of the decoration surface data has been enhanced. The decoration surface has diversified colors, and can be processed into a forest of plates, which can better represent the characteristics of construction and decoration2.

Contact Now

Aluminum tile is made of aluminum plate by rolling and cold bending into various corrugated plates. It has light weight, fast installation, long service life, recyclable and high value. Aluminum plate (profiled aluminum plate, corrugated aluminum plate, antique aluminum plate) has high use value after recycling due to its corrosion resistance, and the recovery rate is more than 80%. Aluminum plate (profiled aluminum plate, corrugated aluminum plate, antique aluminum plate) has good corrosion resistance, waterproof and moisture-proof, maintenance free, and service life of more than 10 years.

Contact Now

Aluminum plateProfessional aluminum plate supplier, providing aluminum plates of various sizes.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is shaped at the surface. The anodized aluminum plate improves its hardness and put on resistance, properly warmness resistance, the melting factor of difficult anodized movie is as much as 2320k, first rate insulation, breakdown voltage resistance is as much as 2000V, complements the corrosion resistance, and does now no longer corrode in high-electricity salt spray for hundreds of hours.

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in various states after the production of these alloys, the machining characteristics change greatly, which requires special machine tools or technologies.FormabilitySpecific tensile strength, yield strength, ductility and corresponding work hardening rate dominate the change of allowable deformation.RecyclabilityAluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum

Contact Now

Aluminum wafers are very common in our life. Aluminum wafers can be found in can sealing, non stick pot bottom, traffic signs, lamp covers, and so on. In addition, aluminum wafers are also frequently used in mechanical manufacturing, automobile and other industrial fields. Therefore, when purchasing aluminum wafers, the primary consideration is the use. The use determines whether to purchase hot rolled or cast rolled materials.

Contact Now

Aluminum plate,Aluminum coil,High quality aluminum oxide sheet.Aluminum oxide plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamps and lighting, consumer electronics, crafts, household appliances, interior decoration, signs, furniture, automotive decoration and other industries.The anodic aluminum plate is oxidized to form a thin layer of alumina on the surface, the thickness of which is 5~20 microns, and the hard anodic film can reach 60~200 microns.

Contact Now

Chengye plate aluminum wafer has some advantages:1. Excellent elongation and tensile strength;2. Good processing performance, high stamping and stretch forming performance;3. Gas welding, hydrogen welding, resistance welding and brazing;4. High plasticity, conductivity and thermal conductivity;5.

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent.

Contact Now

FeaturesCorrosion resistanceThe density of aluminum profile is only 2.7g/cm3, about 1 / 3 of that of steel, copper or brass (7.83g/cm3 and 8.93g/cm3 respectively). Aluminum shows excellent corrosion resistance under most environmental conditions, including air, water (or brine), petrochemical and many chemical systems.conductivityAluminum profile is often selected because of its excellent conductivity. On the basis of equal weight, the conductivity of aluminum is close to 1 / 2 of that of copper.Installation lap diagramSpecification

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7g /, about 1 / 3 of that of iron or copper. Aluminum and aluminum alloy have high strength. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is second only to silver, copper and gold. 3.

Contact Now