Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise referred to as pipe wrapped aluminum coil. There is rock wool insulation layer withinside the wrapped aluminum coil and pipe to shield the thermal diffusion of heating pipe, so it's far referred to as thermal insulation aluminum coil. Thermal insulation aluminum coil typically adopts 1100 aluminum coil and 1060 Aluminum Coil. If the carrier necessities are excessive and the carrier lifestyles is long, 3003 antirust aluminum coil may be used.

Contact Now

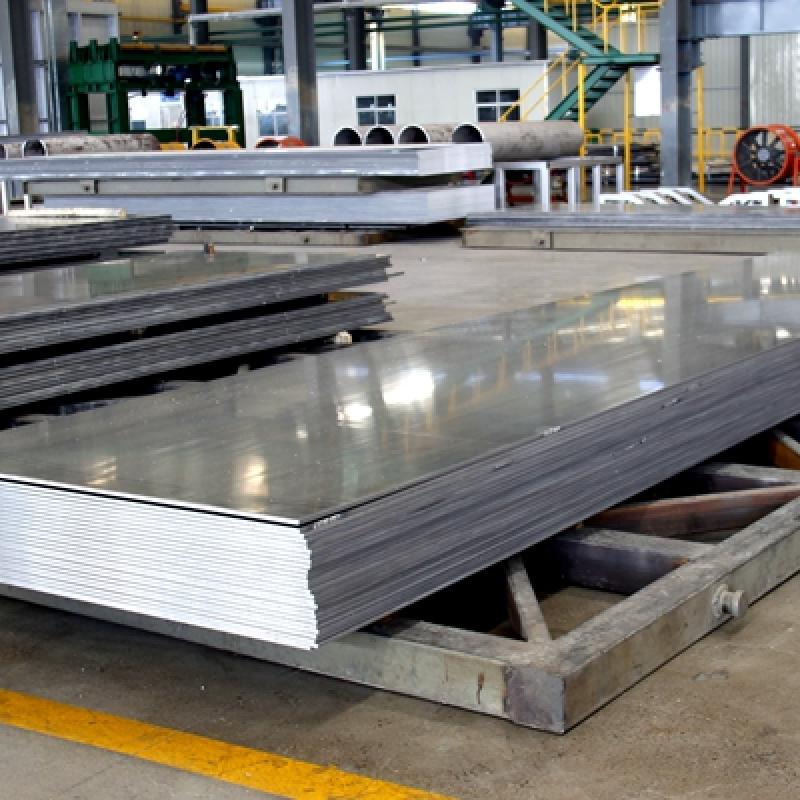

Thermal insulation aluminum coil plate (aluminum sheet) is actually a thin plate of aluminum, commonly known as aluminum coil plate. It can be delivered in flat or rolled form. Due to the poor iron sheet, in recent years, the insulation aluminum coil plate (aluminum sheet) has partially replaced the iron sheet.

Contact Now

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise known as pipe wrapped aluminum coil. there's rock wool insulation layer in the wrapped aluminum coil and pipe to defend the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil commonly adopts 1100 aluminum coil and 1060 aluminum coil. if the provider necessities are excessive and the provider life is lengthy, 3003 antirust aluminum coil may be used.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is formed on the surface. The anodized aluminum plate improves its hardness and placed on resistance, nicely heat resistance, the melting element of hard anodized film is as plenty as 2320k, superb insulation, breakdown voltage resistance is as plenty as 2000V, enhances the corrosion resistance, and does now not corrode in high-power salt spray for masses of hours.

Contact Now

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is also known as pipe wrapped aluminum coil.

Contact Now

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is also referred to as pipe wrapped aluminum coil. there's rock wool insulation layer inside the wrapped aluminum coil and pipe to defend the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil commonly adopts 1100 aluminum coil and 1060 aluminum coil. if the company necessities are immoderate and the company existence is prolonged, 3003 antirust aluminum coil may be used.

Contact Now

The insulation aluminum coil has the function of two layers of insulationTo test the two-layer insulation of the insulation aluminum coil, an aluminum foil is attached to the upper mold of the polyurethane foam. After the foam is formed, the aluminum foil acts as a release agent, while the other side is concerned with the foam, enhancing the wind pressure resistance of the aluminum plate It is enough to illustrate the two-layer thermal insulation of thermal insulation aluminum coil It is highly decorative and different from the structure of other insulation boards at home and abroad.

Contact Now

Aluminum plate,Aluminum coil,High quality aluminum oxide sheet.Aluminum oxide plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamps and lighting, consumer electronics, crafts, household appliances, interior decoration, signs, furniture, automotive decoration and other industries.The anodic aluminum plate is oxidized to form a thin layer of alumina on the surface, the thickness of which is 5~20 microns, and the hard anodic film can reach 60~200 microns.

Contact Now

Thermal insulation aluminum coil has beautiful, durable and practical functionsThe thermal insulation data can be closely connected with the decoration data, so the problem that the thermal insulation data can not be closely connected with the decoration data is solved After contact, it is not easy to fall or loosen, and enhances the wind pressure resistance of the decoration surface data The decoration surface is also diversified in color, and can be processed into various plate shapes, which can better show the characteristics of construction and decoration.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is long-established on the surface. The anodized aluminum plate improves its hardness and placed on resistance, appropriate warmth resistance, the melting component of hard anodized film is as a lot as 2320k, incredible insulation, breakdown voltage resistance is as a lot as 2000V, enhances the corrosion resistance, and does now now not corrode in high-energy salt spray for loads of hours.

Contact Now

Aluminum sheet is one of all aluminum products, which is called aluminum roll or aluminum strip in professional terms. Aluminum sheet is a kind of non-ferrous metal with high aluminum content. It is often used in various large chemical plants, power plants, pharmaceutical plants, oil refineries and other enterprises. It is one of the building materials for thermal insulation and corrosion protection. Aluminum sheet is the embodiment of aluminum ingot. It is repeatedly processed into rough cast roll through massive aluminum ingot.

Contact Now

The selection of thermal insulation aluminum coil should pay attention to cost performance:1. We should not only pay attention to the price when purchasing thermal insulation aluminum coils, but also pay attention to the products based on the price. After all, the price is the same as the goods. We must pay attention to the products whose price is too low to avoid big losses due to greed. Of course, under the same circumstances, we should look at the price, and choose the cost-effective enterprise is our final choice.2.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is formed on the surface. The anodized aluminum plate improves its hardness and placed on resistance, nicely heat resistance, the melting element of hard anodized film is as plenty as 2320k, superb insulation, breakdown voltage resistance is as plenty as 2000V, enhances the corrosion resistance, and does now not corrode in high-power salt spray for masses of hours.

Contact Now

The company mainly deals in: aluminum plate, patterned aluminum plate, alloy aluminum plate, thermal insulation aluminum plate, aluminum oxide plate, brushed aluminum plate, color coated aluminum plate, aluminum coil, aluminum rod, aluminum tube, aluminum strip, aluminum foil and other products. Now the company has hot rolling production line, casting production line, cold rolling production line, shear machine, annealing furnace and other equipment. The company has passed the ISO9001:2000 system certification.

Contact Now

purpose1. Lighting 2. Solar reflector 3. Building appearance 4. Interior decoration: ceiling, wall, etc. 5. Furniture, cabinets 6. Elevator 7. Signs, nameplates, bags 8. Interior and exterior decoration of cars 9. Interior decoration: such as photo frames 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13, mold manufacturing 14, chemical/thermal insulation pipe coating. 15. High quality ship plate

Contact Now

1. Thermal insulation aluminum coil has beautiful and durable functionsThe thermal insulation data can be closely linked with the decoration surface data, so the problem that the thermal insulation data cannot be closely linked with the decoration surface data has been solved. It is not easy to drop or loosen after contact, and the wind pressure resistance of the decoration surface data has been enhanced. The decoration surface has diversified colors, and can be processed into a forest of plates, which can better represent the characteristics of construction and decoration2.

Contact Now

The regular thickness of the heat insulation aluminum sheet pattern aluminum coil pattern aluminum plate embossed aluminum sheet heat insulation aluminum coil is 0.2 mm 0.3 mm 0.4 mm 0.5 mm 0.6 mm 0.7 mm 0.8 mm 0.9 mm. Characteristics of aluminum coil1. The aluminum coil is light in weight. When the price per square meter is calculated, steel and aluminum are almost equal.2. The aluminum coil is easy to process and form, and the construction is convenient and fast, which will reduce the labor intensity of the construction personnel.3.

Contact Now

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise known as pipe wrapped aluminum coil. there is rock wool insulation layer in the wrapped aluminum coil and pipe to guard the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil usually adopts 1100 aluminum coil and 1060 aluminum coil. if the company requirements are excessive and the issuer life is prolonged, 3003 antirust aluminum coil can be used.

Contact Now

Aluminum plates refer to rectangular plates rolled from aluminum ingots, which are divided into pure aluminum plates, alloy aluminum plates, thin aluminum plates, medium thick aluminum plates, and patterned aluminum plates1.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is fashioned at the surface. The anodized aluminum plate improves its hardness and located on resistance, well warmth resistance, the melting detail of tough anodized movie is as masses as 2320k, exquisite insulation, breakdown voltage resistance is as masses as 2000V, complements the corrosion resistance, and does not corrode in high-electricity salt spray for loads of hours.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is fashioned on the surface. The anodized aluminum plate improves its hardness and placed on resistance, well heat resistance, the melting issue of tough anodized film is as plenty as 2320k, super insulation, breakdown voltage resistance is as plenty as 2000V, enhances the corrosion resistance, and does now now not corrode in high-energy salt spray for loads of hours.

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7g /, about 1 / 3 of that of iron or copper. Aluminum and aluminum alloy have high strength. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is second only to silver, copper and gold. 3.

Contact Now

In daily life, we often find the figure of thermal insulation aluminum roll, but when it comes to the purpose of thermal insulation aluminum roll, what is its role. Most people should not know. Next, Foshan Xingkai Aluminum Co., Ltd. will introduce in detail the purpose of thermal insulation aluminum coil and the function of thermal insulation aluminum coil. thermal insulation aluminum coil is a metal material commonly used in anti-corrosion and thermal insulation in power plants and chemical plants.

Contact Now

Corrugated aluminum plate, also known as aluminum tile. It is one of the commonly used products in architecture. At present, there is a trend to replace stainless steel and iron plate.Advantages of corrugated aluminum plate:First of all, since the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of aluminum tile per square meter is less than 1 / 3 of that of stainless steel, which greatly reduces the cost of the enterprise and reduces the pressure of the bracket.Secondly, aluminum has good anti rust effect.

Contact Now