Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

Contact Now

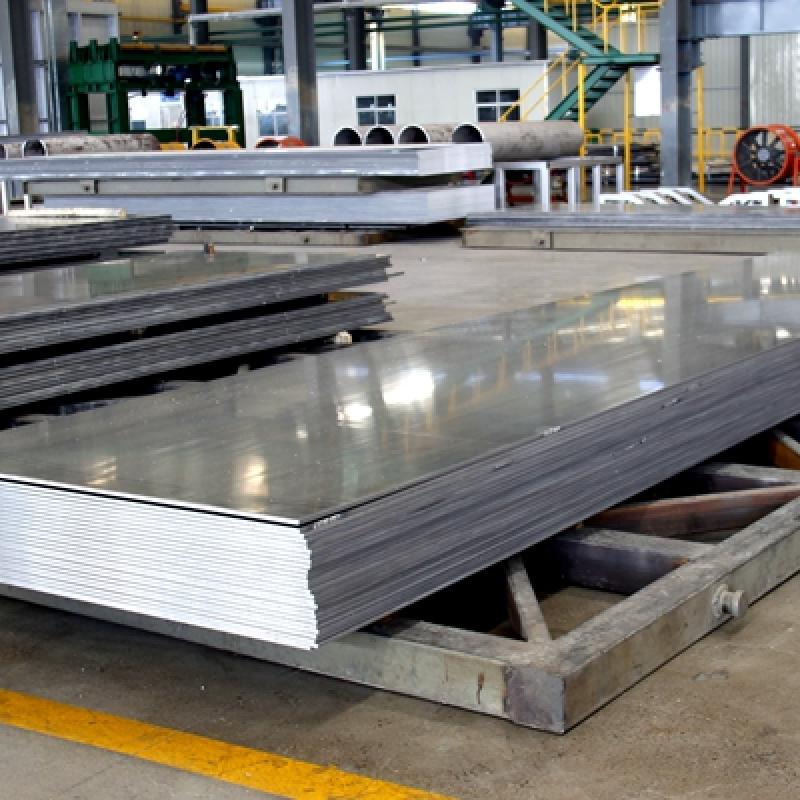

Aluminum plate,Aluminum coil,High quality aluminum oxide sheet.Aluminum oxide plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamps and lighting, consumer electronics, crafts, household appliances, interior decoration, signs, furniture, automotive decoration and other industries.The anodic aluminum plate is oxidized to form a thin layer of alumina on the surface, the thickness of which is 5~20 microns, and the hard anodic film can reach 60~200 microns.

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.Installation lap diagramSpecification

Contact Now

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.advantage(1) Good processability: the positive aluminum oxide plate has strong decorative property, moderate hardness, can be easily bent and formed, and can be continuously and rapidly punched, which is convenient for direct processing into products without complicated

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is prepared 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, similarly to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contact Now

3003 antirust aluminum coil plate has high aluminum content and smooth surface.

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing machine of 3000 collection aluminum coil in China is in particular simple. 3000 collection aluminum coil is specially composed of manganese. The content material fabric material is among 1.0-1.5. It is a chain with accurate antirust function. It is normally carried out in humid environments which includes air conditioner, fridge and automobile bottom. The rate is better than a thousand collection. It is a greater normally used alloy collection.ApplicationPacking

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in various states after the production of these alloys, the machining characteristics change greatly, which requires special machine tools or technologies.FormabilitySpecific tensile strength, yield strength, ductility and corresponding work hardening rate dominate the change of allowable deformation.RecyclabilityAluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is long-established on the surface. The anodized aluminum plate improves its hardness and placed on resistance, appropriate warmth resistance, the melting component of hard anodized film is as a lot as 2320k, incredible insulation, breakdown voltage resistance is as a lot as 2000V, enhances the corrosion resistance, and does now now not corrode in high-energy salt spray for loads of hours.

Contact Now

Aluminum manufacturer,Cheap aluminum sheet,Good quality aluminum plate3003 aluminum plate used for oil tank, gas or oil duct, and other various liquid containers made of deep drawing parts: small load wire used for rivet, kitchen utensils and appliances, food and chemical products processing and storage device, the transportation of liquid product tank, tank, with thin plate processing all kinds of pressure vessel and pipeline General items, heat sink, makeup, copy machine roller, ship material.

Contact Now

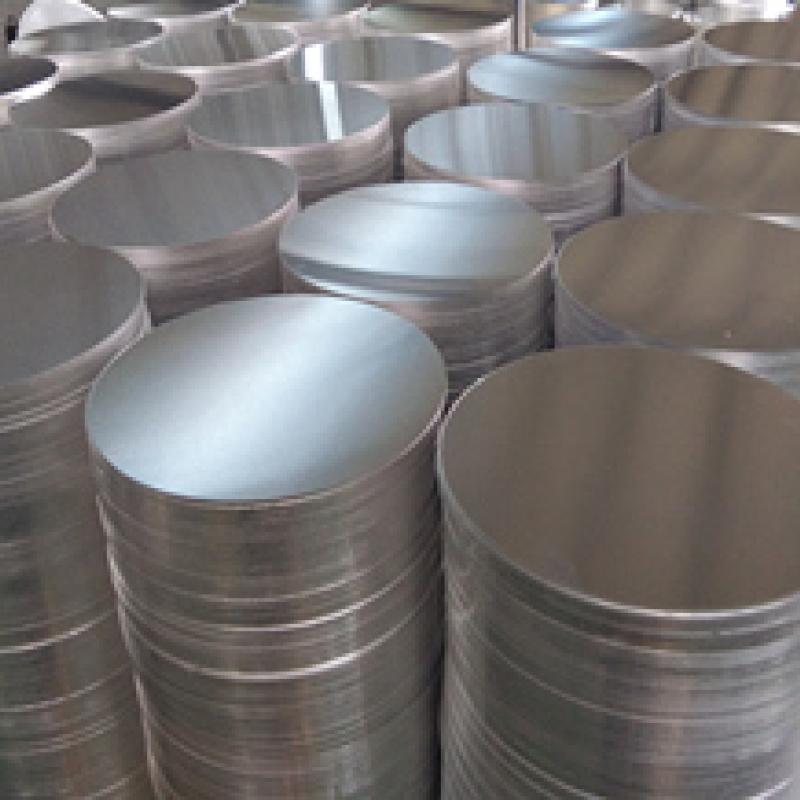

Chengye plate aluminum wafer has some advantages:1. Excellent elongation and tensile strength;2. Good processing performance, high stamping and stretch forming performance;3. Gas welding, hydrogen welding, resistance welding and brazing;4. High plasticity, conductivity and thermal conductivity;5.

Contact Now

Orange skin pattern and diamond shaped aluminum alloy pattern coil: commonly used for packaging pipes or outer packaging.The orange peel aluminum alloy pattern coil is divided into: Classic orange peel pattern aluminum coil, and variant orange peel pattern aluminum coil (also known as insect pattern). Its surface is similar to orange peel pattern, so it can also be called orange peel pattern aluminum plate.

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now

Specific products are as follows:Aluminium (cold rolled sheet) (cold rolled aluminum sheet)Material 1060, 1100, 1050, 8011, 3003, 3004, 5052, 1145, 5083, 6061,Thickness 0.1mm---680mmWidth 800mm----3300mmAluminium coil (cold rolled coil)Material 1060, 1145, 1050, 12008011, 3003, 3004, 5052, 1100,

Contact Now

The company mainly deals in: aluminum plate, patterned aluminum plate, alloy aluminum plate, thermal insulation aluminum plate, aluminum oxide plate, brushed aluminum plate, color coated aluminum plate, aluminum coil, aluminum rod, aluminum tube, aluminum strip, aluminum foil and other products. Now the company has hot rolling production line, casting production line, cold rolling production line, shear machine, annealing furnace and other equipment. The company has passed the ISO9001:2000 system certification.

Contact Now

1. Light weight and high strength Ruiqiao aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) is made of high-quality aluminum coil material, with a density of only one-third of that of steel, light weight and high strength. 2. Good weather resistance Aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) has good corrosion resistance, waterproof and moisture-proof, maintenance free and service life of more than 10 years. 3.

Contact Now

Basic InstructionAluminum coil can also be called antirust aluminum coil. The production process of 3000 series aluminum coil in China is relatively simple. 3000 series aluminum coil is mainly composed of manganese. The content is between 1.0-1.5. It is a series with good antirust function. It is commonly used in humid environments such as air conditioner, refrigerator and car bottom. The price is higher than 1000 series. It is a more commonly used alloy series.PackingApplicationSupport processing customization. Consult the manufacturer for price and attribute details.

Contact Now

Aluminum coil Production detail:1)Alloy: 1050,1060,1070,1100,1235, 3003,3004,3105, 5052,5083,5754, ,6061,80112)Temper: O ,H12,H22,H14,H24,H16,H26,H18,H32, H112 (F) , H111,etc.3) Specification: Thickness: 0.2-150mm Width: 20mm-2200mm &

Contact Now

Typical alloy 5052 aluminum plateMaterial state F, O, H12, h14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114Thickness (mm): 0.1-600Width (mm) 20-2650Length (mm): 500-16000Typical products: aluminum oxide plate, stock bin, automobile aluminum plate, mold, mask machine, electronic stamping parts, can lid, etc

Contact Now

Aluminum sheet is one of all aluminum products, which is called aluminum roll or aluminum strip in professional terms. Aluminum sheet is a kind of non-ferrous metal with high aluminum content. It is often used in various large chemical plants, power plants, pharmaceutical plants, oil refineries and other enterprises. It is one of the building materials for thermal insulation and corrosion protection. Aluminum sheet is the embodiment of aluminum ingot. It is repeatedly processed into rough cast roll through massive aluminum ingot.

Contact Now

Thermal insulation aluminum coil has beautiful, durable and practical functionsThe thermal insulation data can be closely connected with the decoration data, so the problem that the thermal insulation data can not be closely connected with the decoration data is solved After contact, it is not easy to fall or loosen, and enhances the wind pressure resistance of the decoration surface data The decoration surface is also diversified in color, and can be processed into various plate shapes, which can better show the characteristics of construction and decoration.

Contact Now

Thermal insulation aluminum sheet is commonly used in several specifications, generally with a width of 1000mm-2000mm. Other widths are also used, but not particularly. The thickness of aluminum sheet is usually 0.3mm-1.0mm. The length of aluminum sheet is generally divided into two types, one is a large roll of about three tons, which is suitable for large-scale operation, and the other is a small roll of about 50 meters, which is suitable for use in a small space. It is very convenient for two people to use a roll weighing between 50kg and 80kg.

Contact Now

Specific products are as follows:Aluminium (cold rolled sheet) (cold rolled aluminum sheet)Material 1060, 1100, 1050, 8011, 3003, 3004, 5052, 1145, 5083, 6061,Thickness 0.1mm---680mmWidth 800mm----3300mmAluminium coil (cold rolled coil)Material 1060, 1145, 1050, 12008011, 3003, 3004, 5052, 1100, 5083, 6061Thickness 0.10mm----10mmWidth 800mm----1900mmColor coated aluminum coil (embossed color coated aluminum coil (polyester): color coated aluminum coil, fluorocarbon color coated aluminum coil)Thickness 0.024-1.2 (mm) width 800-1220 (mm) 1100 1060 3003 5052

Contact Now

Global delivery,High quality aluminum plate manufacturers,Professional production of aluminum.5052 aluminum alloy sheet use: car aluminum alloy, 3C products, computer support, high-end curtain wall panel, high-end oxidation material, can tank/cover, shutter, pull rod box, aluminum furniture, door/door handle, signs, decoration and other 5052 aluminum alloy thick plate use: Silo, flange material, GIS shell, yacht, underwear mold/shoe mold, air storage cylinder, mask machine, mask machine, precision machining, etc.5052-H32 aluminum plate is used in the category of car aluminum: car engine outer

Contact Now